The Growing Importance of Multi-Network Support and Design Challenges in Industrial Automation

With the automation demand increasing in the manufacturing industry in recent years, it is now important to provide a diversity of network support for industrial controller equipment such as PLCs, motion controllers, and CNCs. The controller equipment requires the support of Industrial Ethernet (IE) controllers such as EtherCAT and PROFINET to communicate with equipment as a network device like servos and inverters. On the other hand, there are also cases where multiple protocols are simultaneously supported, and the same protocol is used for multiple networks. It is also necessary to implement general-purpose Ethernet for communication with factory management systems and HMI equipment such as motion controllers, CNCs, and small PLCs that use IE to connect to the main PLC. In factories where equipment and systems from different manufacturers are used, it is also important to support multi-protocol IE to support the IE protocol used at the shipping destination. Hence, the development of industrial controller equipment needs to ensure flexible support network requirements, such as multi-protocol support for both IE controller and device and implementation of multiple ports of general-purpose Ethernet.

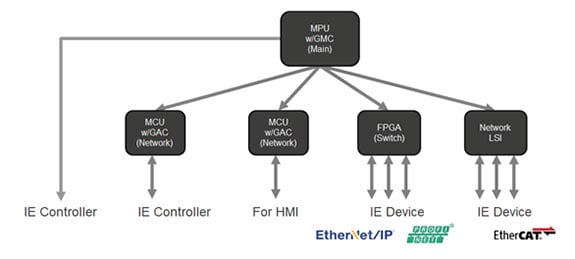

To support various protocols and multiple Ethernet ports, on top of the main processing MPU, it is necessary to add a dedicated communication LSI for EtherCAT or PROFINET or FPGA programming hardware or a general-purpose microcontroller that can flexibly respond to network requirements. In addition to Ethernet support, each device requires its own power supply and memory, and communication between the main MPU and the additional devices must also be implemented – making the hardware design more complex.

Flexibly Support a Wide Range of Network Requirements with a Single Chip

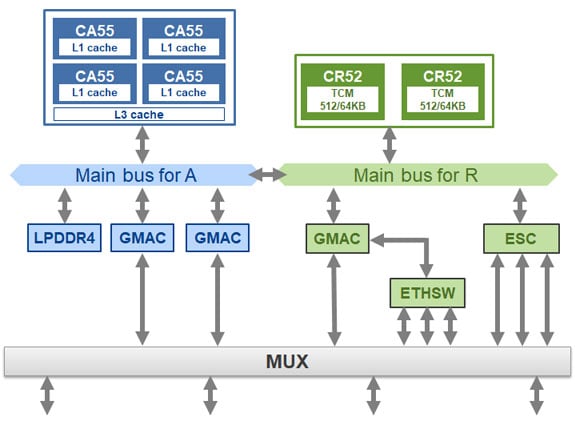

To realize the network requirements mentioned above, it is important to select an MPU that is equipped with a CPU supporting a wide range of networks, peripherals, and operating systems. The RZ/T2H MPU is equipped with the best-in-class Quad Arm® Cortex®-A55 1.2GHz as application CPUs and DDR IF supporting LPDDR4-3200 32-bit as a high-capacity, high-speed memory with the capability to operate Linux operating system, which is widely used for IE controllers. In addition to the application CPUs, two Arm Cortex-R52 CPUs are embedded into RZ/T2H as real-time CPUs, and a large amount of tightly coupled memory (TCM) – 576KB – is embedded in each CPU for real-time control. It eliminates jitters of execution time and realizes deterministic high-speed response processing, making RZ/T2H an ideal MPU for IE devices requiring a response to the controller in a predetermined cycle. In terms of network functions, RZ/T2H has an EtherCAT Slave Controller (ESC), a three-port Ethernet switch (ETHSW) for PROFINET and EtherNet/IP, three channels of Gigabit Ethernet Macs (GMAC), and a multiplexer for flexibly connecting between these functions and four external ports. RZ/T2H is a single MPU that can support various network requirements reducing hardware design man-hours and enabling designers to build smaller PCB boards with a lesser number of components.

Taking PLC as an example, GMAC can be assigned to a total of three ports – two ports for IE controller and one port for general-purpose Ethernet for connection to monitor systems and HMIs. As for motion controllers and CNCs, two of the four ports can be used as an IE device such as EtherCAT, and the remaining two ports can be used as an IE controller.

| Combination | Port 0 | Port 1 | Port 2 | Port 3 |

|---|---|---|---|---|

| 1 (Example of use: PLC) | IE Controller (GMAC) | IE Controller (GMAC) | Surveillance System/HMI (GMAC) | ー |

| 2 (Example of use: motion controller, CNC) | EtherCAT Devices (ESC) | IE Controller (GMAC) | IE Controller (GMAC) | |

The RZ/T2H MPU gives users the option to select the most suitable CPU from the application CPU and the real-time CPU according to the communication purpose, and flexibly supports IE controller, device, and general-purpose Ethernet with abundant network functions to reduce the number of components such as dedicated communication LSIs. Also, if a different network request arises during model deployment, it can be done by changing the assignment to the external port in software without changing the hardware, which greatly contributes to the reduction of hardware development cost.

Evaluation Board, Sample Program Needed for Network Platform Development

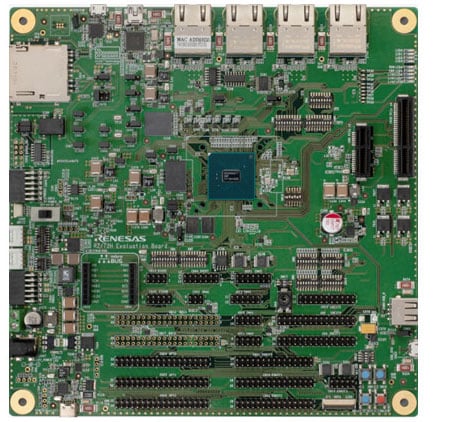

The EVK-RZ/T2H is equipped with all the necessary components such as a large capacity LPDDR4 memory and four Ethernet connectors in the RZ/T2H, enabling the development of various network software.

Users can also download sample programs for Linux and FreeRTOS to jumpstart the development with the EVK. There is also a wide selection of sample programs for IE controllers and devices – OPC UA and EtherCAT – as well as for networks such as general-purpose Ethernet available on the Renesas website. By downloading various sample programs and using them together with the evaluation board, you can immediately start your next network development with RZ/T2H MPU.

For more information, visit renesas.com/rzt2h