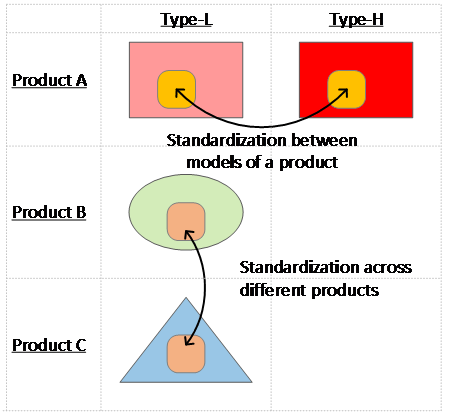

These days, design standardization is one of the requests we receive the most. The benefit of it is to reduce not only the component cost but also the maintenance workload in the future. In particular, the industrial sensing equipment, which is the main target of the RX23E-A 32-bit microcontroller (MCU), offers a long product lifecycle and diverse specifications, so we could say that the benefit of standardization is even more significant.

There are generally two directions for standardization. One is using models of the same product. For example, the standardization from high-end models to low-end models. Another one is across the different products. For example, the standardization between a pressure gauge and a thermometer. In this blog, I will introduce the former, an example of standardization within the same product, which the RX23E-A MCU has played to achieve.

In the RX23E-A’s lineup, we have the RX23E-A/2 units with two units of delta-sigma ADC and the RX23E-A/1 unit that has only one unit of delta-sigma ADC. In some cases, design standardization can be achieved by adopting the RX23E-A/2 units or RX23E-A/1 unit appropriately. Let me introduce a few practice examples here, some including my assumption.

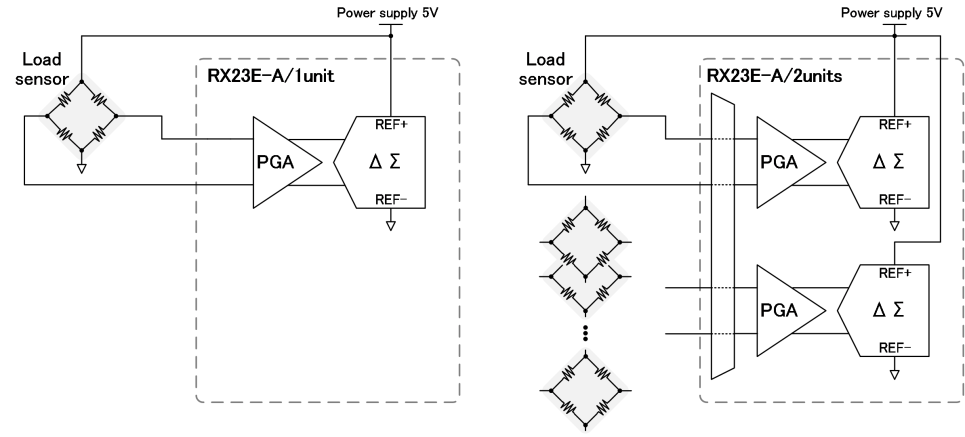

Example 1: Load Measurement

The first is an example of load measurements such as weight, force and torque measurement. There are so many diverse models in load measurement applications. The simplest one is a model with one load sensor and one unit of delta-sigma ADC as shown in the left figure below. However, depending on the mechanical structure, the required precision/accuracy, and the measurement cycle, some models must have multiple load sensors and multiple units of delta-sigma ADC as shown in the right figure. For example, in a high-end model for a weight scale, four strain sensors are placed at the four corners of the checker’s platform to improve precision. By adopting the RX23E-A/1 unit or RX23E-A/2 units properly, standardization could be applied in such a wide variety of models like this.

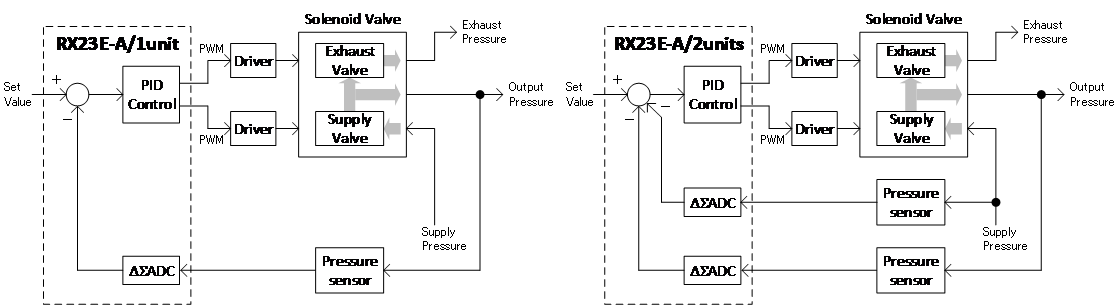

Example 2: Pressure Controller

The second is an example of a pressure controller application. The mechanism of the pressure controller is described below.

- When the supply valve is ON and the exhaust valve is OFF, the supply pressure is supplied to the output side, increasing the output pressure.

- When the supply valve is OFF and the exhaust valve is ON, the output pressure is decreased.

- By repeating the above two operations, the pressure is controlled constantly.

In a general-purpose model, the control system has only one pressure sensor measuring the output pressure as shown in the left figure. On the other hand, in a high-end model, the control system has two pressure sensors, one measuring the output pressure and the other measuring the supply pressure as shown in the right figure. The limitation of the configuration in the left figure is when the supply pressure varies, the variation of the output pressure would be large, and the settle time would be long. In contrast, the configuration on the right could solve the limitation by additionally measuring the supply pressure. Then again, by adopting the RX23E-A/1 unit or /2 units properly, a general-purpose model and a high-end model could be standardized.

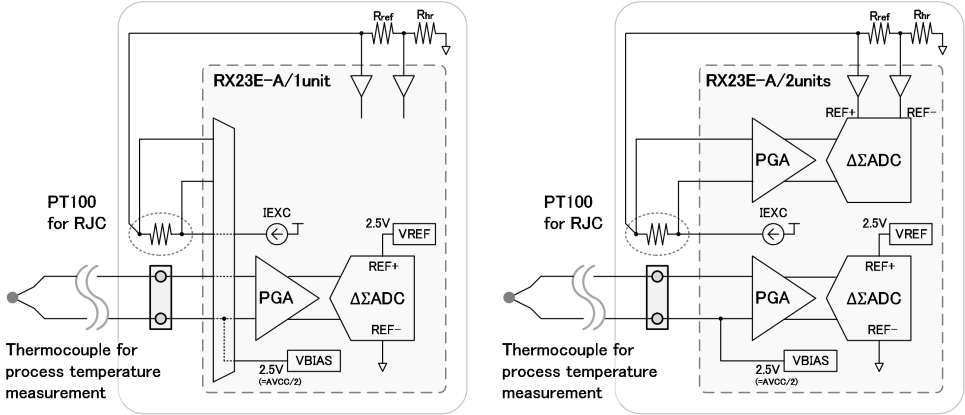

Example 3: Temperature Measurement

The third is an example of temperature measurement using thermocouples.

When measuring temperature with thermocouples, it is necessary to measure the reference junction temperature (RJC) in addition to the temperature of the thermocouple itself. For RJC, a PT100 is generally used. Since temperature changes relatively slowly compared to the examples described above, many models use a MUX to switch measurements of the thermocouple and the PT100 for RJC alternatively as shown in the left figure. However, some models implement the measurement of the thermocouple and the RJC simultaneously. In these cases, a low cost digital temperature sensor is used for the RJC. It means the way to measure the RJC varies among models and is desired to mitigate by design standardization.

RX23E-A/2 units allows for measuring the thermocouple and the PT100 for RJC simultaneously as shown in the right figure. By adopting the RX23E-A/1 unit or /2 units properly, a digital temperature is not required, and the parts can be standardized as well.

Finally, I would like to emphasize that the RX23E-A/2 units and RX23E-A/1 unit are pin-compatible, and the development tools can be shared as well. Although this blog focuses on standardization in terms of hardware, software standardization is certainly possible.

In the next blog, I will introduce standardization across the different products.