The most important way to achieve better heat dissipation is to decrease the thermal resistance of the semiconductor device. The factors that determine thermal resistance are described in detail below.

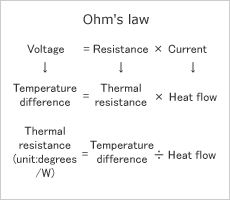

Thermal Resistance that can be Calculated in the Same Manner as Ohm's Law

Thermal design that considers heat dissipated from semiconductor devices uses the concept of "thermal resistance," based on the fact that heat transfer can be compared with the way electricity is transmitted.

In the case of electricity, the relationship among voltage (electric potential difference), current, and resistance is expressed by Ohm's law, as shown below. Heat resistance can be calculated using a law similar to Ohm's law by replacing voltage with temperature difference, current with heat flow, and resistance with thermal resistance.

As can be seen from the above expression, thermal resistance indicates how readily heat is dissipated.

The Four Factors that Determine the Thermal Resistance of a Package

The overall thermal resistance of a package is almost entirely determined by:

- Package structure

- Chip dimensions

- Air flow rate

- Package size

Each of these elements influences the thermal resistance as follows.

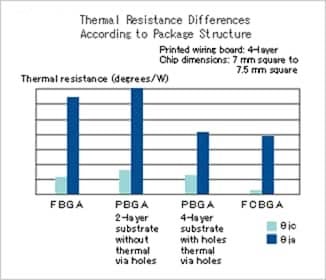

Thermal Resistance Differences According to Package Structure

Package structure

Packages come in various types, each with different thermal resistance characteristics (refer to the diagram above). Packages such as FCBGA, which features a copper lid to which the chip is directly attached, offer excellent thermal resistance characteristics. In the case of PBGAs, thermal resistance can be lowered by using a 4-layer substrate instead of a 2-layer substrate, and it can be further lowered by placing solder balls directly underneath the thermal via holes.

Chip dimensions

The thermal conductivity of silicon chip is about 100 times higher than that of mold resin and about 10 times higher than that of package substrates; therefore, the chip size is a major contribution factor to the heat conductivity.

Air flow rate

Forced air cooling, including fan cooling, does not affect the thermal conductivity of the package but efficiently removes heat from the package surface or PWB to the atmosphere, and thus lowers overall thermal resistance.

Package size

Generally, larger package is said to have a better thermal conductivity. It is true for FCBGA, which has a large copper lid offering excellent thermal conductivity over a package. But for the packages with lower thermal conductivity such as FBGAs, package sizes do not much help enhancing thermal conductivity; therefore, there is little variation in thermal resistance among different size packages if the chip dimensions are the same.