Renesas Electronics recently issued its 2023 Business & Sustainability Report, which reflects a long-term commitment to a more sustainable future for customers, employees, partners, and investors. These ongoing global initiatives span from greenhouse gas emission (GHG) reduction to improved supplier engagement and social contributions that demonstrate our dedication to fulfilling our purpose and promise – To Make Our Lives Easier.

Charles Kawashima, Renesas Vice President and newly appointed Head of the Sustainability Promotion Office, spoke with Dr. Sailesh Chittipeddi, Executive Vice President and Head of Operations for Renesas, who is responsible for all global internal and external manufacturing, including supply chain, procurement, and process, package, and test platform development.

Charles: Sailesh, 2023 was a year of headwinds for the semiconductor industry given factors such as geopolitical uncertainties, global inflation, and rising interest rates. In the face of these challenges, how did Renesas advance its sustainability goals in the area of operations internally and externally?

Sailesh: As a result of our efforts over the past several years, Renesas is positioned to effectively manage our internal operations, our foundry operations, and our external operations together with procurement and supply chain as an integrated operations team.

In collaboration with our Environmental Promotion Department, our production teams at Renesas factories and around the world are striving to meet our global targets through advanced manufacturing processes. This includes a close partnership with all of our suppliers, which is critical to achieving our goals. It's a holistic cycle. What customers ask of us, we ask of our suppliers and our internal factories. Supplier engagement has been our top priority and we are proud of our continuous efforts resulting in the recognition as a Carbon Disclosure Project (CDP) Supplier Engagement Leader for two consecutive years.

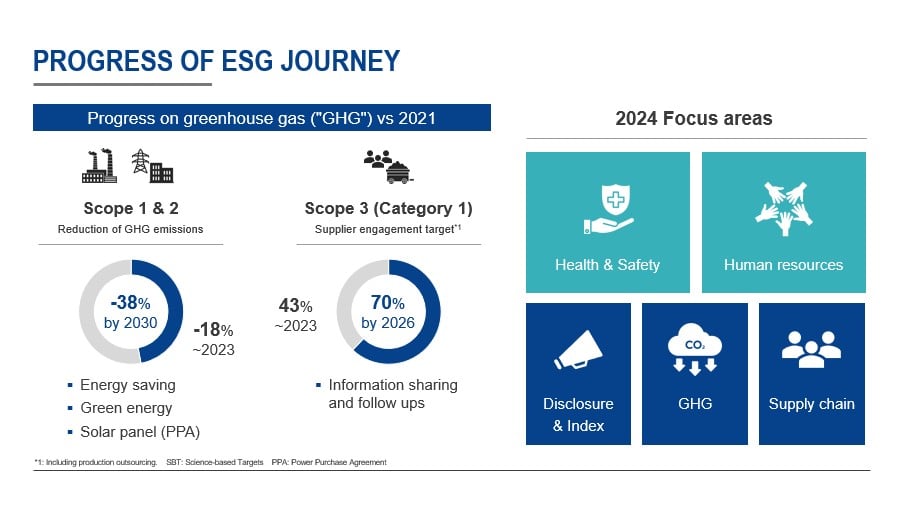

Charles: What are the accomplishments and progress related to climate change we made in recent years, such as GHG emission reduction?

Sailesh: We have reduced our own Scope 1 and 2 GHG emissions by saving energy, increasing the use of green energy sources, and investing in technologies such as gas abatement equipment. That is designed to enable us to achieve a 38% emissions reduction by 2030 (using 2021 as the base year) and full Scope 1 and Scope 2 carbon neutrality by 2050. We’ve already recorded a 17.9% emissions reduction in 2022-2023 compared to 2021.

Also, about two-thirds of our emissions come from supplier sources, also known as Scope 3 or value chain emissions, which refers to emissions occurring both upstream and downstream. Because Scope 3 compliance is voluntary, it requires efforts across the entire supply chain to significantly impact our progress in this area. We are currently working with suppliers in Category 1 of Scope 3 to set GHG emission reduction targets. Our goal is to have 70% of our suppliers set goals certified by the Science Based Targets initiative (SBTi) by 2026.

Charles: How does Renesas plan to advance these objectives in the year ahead?

Sailesh: A key component of our program includes annual supplier audits. This year we are striving to achieve 80% participation in these surveys in addition to placing a strong focus on human rights.

There's a lot of learning to be had here because some of our bigger suppliers have been down this path. Whether it comes to water and waste recycling or GHG reduction, they've done an outstanding job, and there are practices we can learn from them that we can implement in our own factories.

We’re also keen to increase training throughout our supply chain to support our partners in their efforts to improve their own environmental and operational performance. This is important, because a lot of our suppliers are smaller companies, and I see it as our responsibility to carry the torch for them in order to teach, inspire, and train. The impact will be beneficial for all participants up and down the Renesas supply chain.

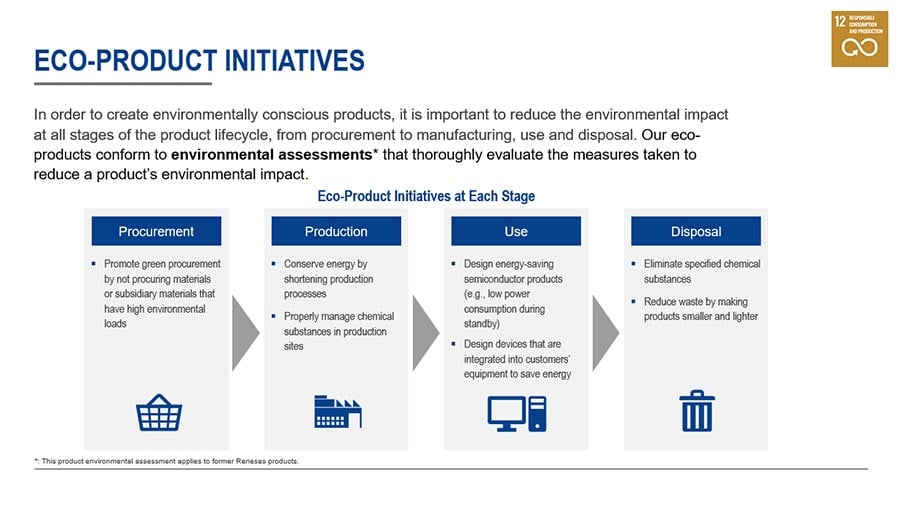

Charles: How is Renesas using its own technology leadership position to advance sustainability goals?

Sailesh: One approach that excites me is the incorporation of artificial intelligence (AI), which is already helping optimize product development and minimize risks and costs at our factories around the world.

In the areas of design and testing, AI-enhanced embedded technologies improve the accuracy of equipment monitoring, resulting in increased productivity. An example would be the detection of minute gas leaks in process equipment, which allows us to notify a maintenance team and extend the life of equipment as well as protect the health and safety of our teams.

I think, right now, AI is approaching a state where it's reshaping our landscape, whether it's factory yield enhancement, preventive maintenance and detection, or improved equipment utilization that helps to minimize chemical use. And, we're already using tools from our suppliers that allow us to use AI techniques to optimize power, performance, and area.

Charles: Thank you, Sailesh. It’s exciting to see the advancements we have made. I am looking forward to working with your team, our suppliers and customers, and virtually every other organization within Renesas to continue our positive momentum and accelerate our progress in this critical area.