With the rapid spread of highly contagious diseases around the world, using non-contact thermometers is now becoming a medical necessity. Detecting viral and bacterial infections requires precise body temperature measurements, preferably without contact, so medical personnel can help prevent the spread of disease within the healthcare system. According to a report by Research and Markets, globally, the non-contact thermometer business outlook is expected to increase at a CAGR of over 11% from 2018-2024.

This growth in non-contact thermometers is expected primarily in North America and APAC, but all regions are expected to see an increase. The reason for this growth is our aging population, which is most susceptible to infections when they are going to their healthcare provider or in permanent care. As the consciousness of cross-contamination and secondary infections continues to increase, these non-contact solutions are quickly beginning to replace in-ear and forehead thermometers. Other applications driving these solutions are veterinary and home care. In both cases, it is preferred that an easy-to-use, compact, and accurate contactless type of solution with a long battery life is utilized.

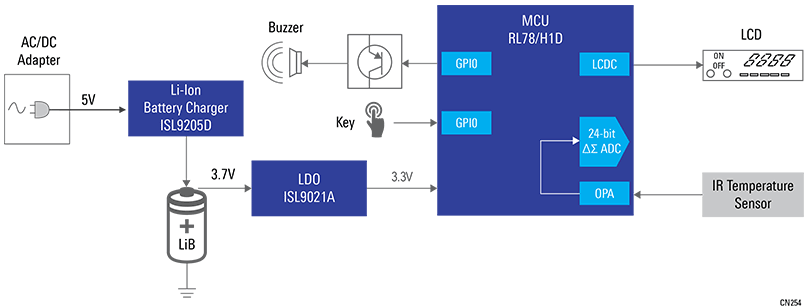

The IR Contactless Thermometer block diagram in Figure 1 is a typical example of a non-contact type of thermometer application. The heart of this solution is the RL78/H1D microcontroller. It includes high-precision analog functions such as a 24-bit Delta-Sigma A/D converter, SAR A/D converter, programmable gain amplifiers, an operational amplifier, and an 8-bit/12-bit D/A converter. It also has a built-in LCD controller/driver, which makes the RL78/H1D well-suited for healthcare devices. This lower power consumption and heavy integration within one MCU allows the system to have a longer battery life and smaller solution size. Moreover, the RL78/H1D has a wide input range of 2.7V to 5.5V. This makes the RL78/H1D a better fit for battery applications. The RL78 also provides an option of a 64-pin 4x4mm TFBGA package, allowing for an extremely compact board design.

To manage the power supply for the whole system, we use the ISL9021A. This is a line of Renesas’ low IQ, low noise, and high PSRR LDOs, which is the best fit for battery applications. Its input voltage range is between 1.5V to 5.5V and the output voltage comes in many fixed voltage options, with ±1.8% accuracy over-temperature, and line and load ranges. The ISL9021A has a typical PSRR of 75dB at 10kHz and 50dB at 1MHz, which enables the LCD in the system to get low noise and stable power. It is also offered in tiny 4-bump 0.975mmx1.155mm WLCSP and 1.6mmx1.6mm 6 Ld µTDFN packages. This makes it well-suited for small board development in battery-powered handheld devices.

To manage the battery charging portion of the design, we used the ISL9205D, an integrated single-cell, Li-Ion or Li-polymer charger. This family of devices operates as a linear charger when the AC adapter is a voltage source. The battery is charged in a standard Li-Ion charge profile, that is, a constant current phase followed by a constant voltage phase (CC/CV). When the adapter output is a current-limited voltage source and the current limit is smaller than the programmed constant current of the IC, they will operate as a pulse charger, where the charge current is determined by the current limit of the AC adapter during the constant current phase. The ISL9205D operates in a linear mode during the constant voltage phase in both adapter cases. It is also offered in small 3x3mm QFN or DFN packages, making it small enough to fit into medical solutions.

By using a high-integration MCU, a low IQ voltage regulator, and a Li-Ion battery charger – all in extremely small packages – we have provided a compact, cost effective, low power non-contact thermometer design.

Figure 1 – IR Contactless Thermometer block diagram:

Visit the winning combinations page to see more solutions that help our customers accelerate their designs to get to market faster.