How is everyone coping in this global Covid-19 pandemic? Awareness of social distance has become commonplace in daily life, and it is getting troublesome on the need to disinfect or use gloves each time you need to touch things or make contact with people. In the future, it is expected to have more control handled by machines instead of contact between people, hence a human machine interface (HMI) is important for products in the New Normal era.

In the first section, I will introduce the “non-contact button” enabling HMI operation without a direct touch on the button contributing to the product development meeting the needs of the New Normal. In the second half, I will introduce a user-friendly Graphic User Interface (GUI) lowering the barriers to GUI development using an LCD. Finally, an additional bonus on introducing the voice recognition solution.

Firstly, let me introduce the non-contact button solution.

Touch keys have been adopted as input for HMI in various fields such as industrial equipment and household appliances, as well as home electronics and healthcare devices in recent years due to sophisticated design and the ability to provide a high level of usability. Higher usability will be required in the future as these applications become more popular.

The RX touch key solution has a high sensitivity that can detect the approach of a finger through a 10mm thick, acrylic plate, and is high noise resistance, passing the IEC 61000-4-3, 4-6 Level 3 severe noise test. This allows the detection of a finger, even when wet or when wearing gloves. Beyond buttons that can be operated with the touch of a finger, you can also develop buttons that operate in a non-contact manner.

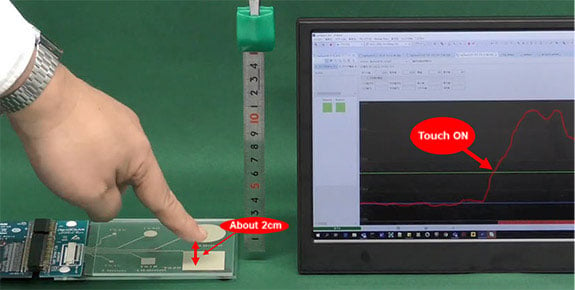

The figure below shows an example of the development of a non-contact button that can be operated, without direct touch.

Capacitive Touch Evaluation System for RX130 3cm × 3cm film electrode

The following environment was used for program development.

Table 1. Program development environment

PC | |

Emulator | |

Evaluation board | Capacitive Touch Evaluation System for RX130, 3cm × 3cm film electrode |

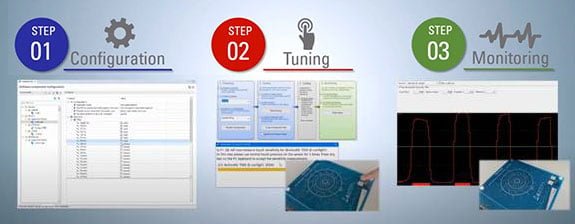

Touch sensitivity can be adjusted with a simple three-step process using Renesas' free touch development support tool - QE for Capacitive Touch.

The touch key is affected by the material substrate, the shape of the electrode and the surrounding environment, making it difficult to adjust, even for users with development experience. However, it is easy to perform automatic tuning of touch sensitivity when you use this tool along with the initial setup of the touch interface from the basic software settings.

- First, set up the software needed to detect the touch sensor. This can be set by performing a simple operation on the GUI.

- Adjust the touch detection sensitivity. In this development process, we adjusted it to detect ON/OFF when the distance between the finger and the film electrode was about 2cm. The project is complete once the parameters are set and you have completed the remaining steps.

- Write the project to the board and test the touchless detection. When a finger is gradually brought closer to the button, the count value rises, and when the distance from the electrodes approaches about 2cm, the count value exceeds the threshold value, and a touch “ON” is detected safely!

The Renesas RX microcomputer touch solution easily enables the development of a touchless UI, using an RX130 capacitive touch evaluation board and the touch sensitivity adjustment tool, QE for Capacitive Touch.

Anyone can use it right away by watching the QE for Capacitive Touch tutorial video for step-by-step instructions on how to use QE for Capacitive Touch. Please refer to the application note, “CTSU Basis of Cap touch detection” for more information on improving touch sensitivity.

Next-up is a solution that makes it easy to develop a graphic UI (GUI) using an LCD.

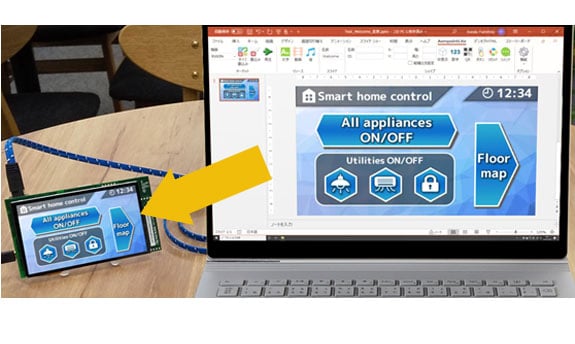

Do you think that it is very challenging for first-time engineers to design a sophisticated GUI like the image shown above, with the use of an embedded graphics tool and a C language program for the embedded microcontroller board?

Actually, this image was created with the PowerPoint software, which we use every day. It doesn't use any specialized graphics tool, and we didn't develop any cumbersome program.

This GUI design tool is known as the “Aeropoint® GUI for RX” provided by CRI Middleware Co., Ltd. (hereafter, CRI). The great thing about this tool is that you can develop a GUI easily and quickly using PowerPoint, a software that everyone uses to create presentations. Below are the steps needed to create a GUI.

- Connect the kit to a PC.

- Start PowerPoint and create the design image on the slide.

- Click on the “Write All” button.

With only three steps, the designed image appears in the kit!

Refer to the "Developing GUI for the Embedded With Your Familiar PPT? Installing a Color LCD Without Programming" blog to learn more about “Aeropoint® GUI for RX.”

The RX72N Envision Kit is ideal for GUI design as it is not only equipped with a WQVGA LCD, but also has a wealth of extended I/F.

The bonus section on voice recognition solution.

We heard many customers in recent years who want to control their devices through voice, especially in the consumer electronics field. The RX microcontroller voice recognition solution does not require an Internet connection and is highly responsive to trigger words and is noise-resistant to the surrounding environment. Visit the voice recognition website to find out more.

I was shown a demonstration for touch key solutions at an exhibition when I was a student, and I was really excited by its high level of design, operability and the many ways you could use it, that leads me in joining the company because I wanted to develop appealing solutions. While supporting our customers, we solved issues such as barriers to the introduction of touch keys and the fine-tuning of parameters through the introduction of automated adjustment tools and support for electrode design. We will continue to prepare appealing solutions contributing to our customers, without forgetting the happiness we feel when we receive words of thanks and compliments.

In addition to the solutions introduced in this article, Renesas Electronics RX microcontrollers offer a variety of solutions that lower development hurdles. Learn more at the RX Family website.