Pressure measurement is indispensable in the precise and accurate control of automotive subsystems to ensure safety, performance, and accuracy. The key to achieving a high degree of safety, performance and accuracy is the sensor signal conditioner (SSC) integrated circuit. In recent years, the rapid technological advances have revolutionized the automotive industry and a wide variety of new sensors have been introduced to address pressure sensing in braking, transmission and HVAC applications in xEV, PHEV, FCEV and BEV vehicles. The increasing technical and legal requirements from regulatory authorities have led to strengthened requirements for robust pressure sensors in vehicles while the cost of such devices must remain low due to the strong competition in the market.

In this blog, let’s discuss Renesas RAA2S425x family of piezoresistive sensor signal conditioners targeting 3 key areas: braking systems, transmission and HVAC applications in xEV, PHEV, FCEV and BEV vehicles.

1. Braking systems in xEV, PHEV, FCEV and BEV Vehicles

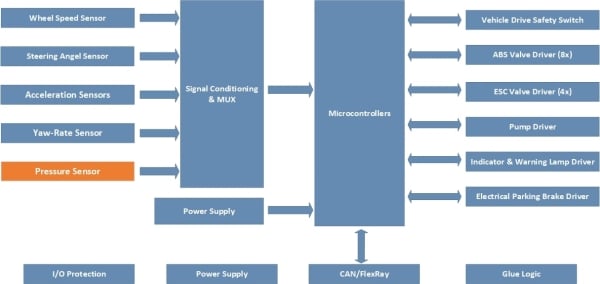

Several of the greatest advances in automotive technology in the past 20 years are in the area of safety management particularly targeting braking systems. Many of these include well-known standard systems such as antilock braking system (ABS) and electronic stability control (ESC) in xEV, PHEV, FCEV and BEV vehicles, greatly reduce the risk of a fatal crash whilst ensuring the safety of passengers. Based on different sensor input signals, the precise control of the hydraulic modulator ensures that each wheel has the right braking force at the right time. The fault statuses are monitored by the control unit and displayed to the driver. The electric park brake option further enhances vehicle safety and driver comfort.

In order to ensure maximum safety of the driver and the passengers, braking systems must ensure ASIL- compliance according to ISO26262. Renesas RAA2S425x family offers high performance and highly accurate RAA2S4253B, ASIL-B compliance according to ISO26262 pressure sensing chip, enabling OEMs and Tier1/Tier2 suppliers to build ASIL-C & ASIL-D braking (sub-)systems to meet the highest safety requirements, in addition to ensuring long-term accuracy and reliability in a harsh automotive environment.

2. Transmission in xEV, PHEV, FCEV and BEV Vehicles

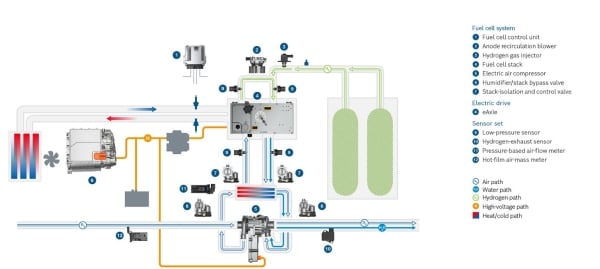

FCEV uses hydrogen to power the vehicle as promising green energy-based alternative compared to internal combustion engine (ICE). With water as their only output product, hydrogen FCEVs produce best case zero emissions, which is one of the main reasons why they are being considered as a solution to CO2 reduction. Fuel cell’s potential is extremely promising, and the necessary advanced research to optimize performance and successful integration into a vehicle’s architecture is well underway.

When looking at Renesas RAA2S425x product family, it offers complete pressure sensing from high-pressure H2 tank (upstream) to low pressure air-intake (downstream) in FCEV transmission system. This would enable OEMs and Tier1/Tier2 suppliers to use Renesas as one-stop-shop reliable partner to overcome supply chain issues whilst benefiting from a world class product family.

3. HVAC in xEV, PHEV, FCEV and BEV Vehicles

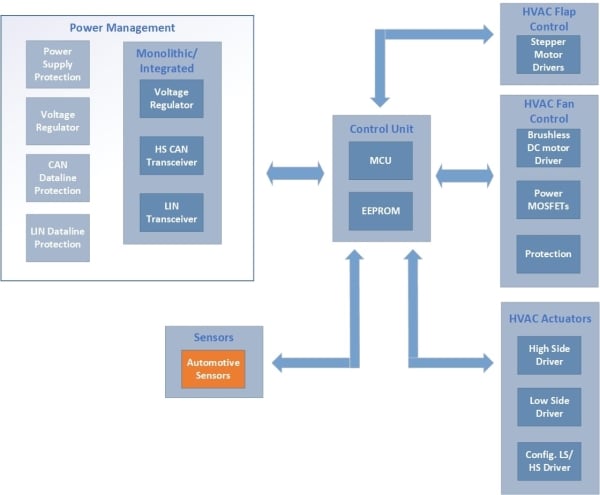

HVAC automotive systems use pressure and temperature sensors and switches to control basic operations of the system such as turning it on or off or for opening or closing valves or vents. HVAC may consume a substantial amount of the total energy stored, considerably reducing the vehicle range, which is one of the most important parameters for EV acceptability. Therefore, low power consumption of the HVAC is fundamental in xEV, PHEV, FCEV and BEV vehicles.

The power consumption of the HVAC and thermal management systems depends greatly on both the ambient temperature and how the vehicle is being driven, as well as on the system’s key components (whether it includes an electric coolant compressor or a heat pump). Integrated HVAC systems are attractive to both vehicle OEMs and Tier1/Tier2 suppliers. OEMs benefit from lower engineering, assembly and component costs, along with optimized thermal management, while Tier1/Tier2 suppliers can gain a competitive advantage from going beyond offering components, modules and subsystems to manage trade-offs in terms of efficiency and cost.

Renesas RAA2S425x product family, when used in a HVAC system, ensures accurate measurement of the pressure signal whilst low power consumption of the IC itself which means optimal performance to support temperature range defined by AEC-Q100 standard and lower power consumption of the entire HVAC electric coolant compressor or a heat pump-based system.

Synopsis of RAA2S425x Product Family

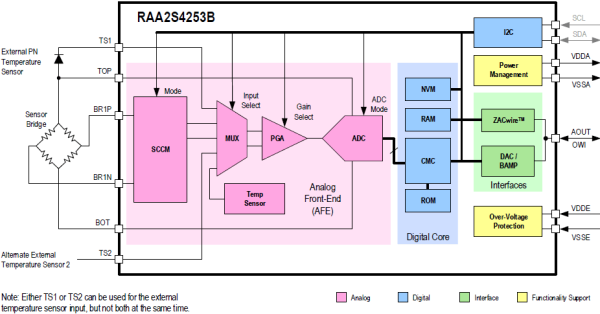

Renesas recently introduced the RAA2S425x product family of piezoresistive sensor signal conditioners. These new devices provide highly accurate differential bridge signal amplification and sensor-specific linearization and correction to address pressure sensing applications namely braking, transmission, and HVAC in xEV, PHEV, FCEV and BEV vehicles. The RAA2S425x features high integration and advanced digital and analog functionalities that significantly improve the design cycle and contribute towards reducing customers’ BOM (less external components) and production costs (digital calibration, using OWI interface, reduces assembly costs by eliminating the need to perform laser trimming of sensing element).

The RAA2S425x ICs support all major pressure sensing technologies and feature a high-performance analog front-end (AFE) for enhanced signal conditioning. The new devices offer extended analog sensor offset compensation (XSOC), adjustable to nearly all resistive bridges. They deliver pressure and temperature readings with high accuracy (0.35% – 1.0%) over a wide temperature range (-40°C to 150°C), offering effective ADC resolution of 13 to 18 bits, and ASIL-B compliance according to ISO26262 (offered by RAA2S4253B).

For more information about the RAA2S425x family of SSCs, visit Automotive Sensor Signal Conditioners (SSC/AFE) or get your evaluation kit today to complete your next system design!