We live in the Digital Age. But when it comes to enabling the future through semiconductor engineering, how often do we really examine what that means? At Renesas, we have embarked on a journey of digital transformation – for ourselves and for the benefit of our customers. A key goal of that quest is to help our industry find a better way to facilitate what has become a fractured electronics design process, one in dire need of rationalization, simplification, and broader collaboration.

The IT journal Channel Insider assigns three tiers to the digital landscape. The first, "digitization," is the conversion of real-world analog phenomena such as sight, sound, temperature, and pressure into a digital format of 1s and 0s. The second, "digitalization," is the structure, or plumbing, through which digital data is applied to business and operating processes. These enable the third tier, "digital transformation," in which enterprises harness AI, cloud computing, and IoT solutions to "create new or significantly improved business models."

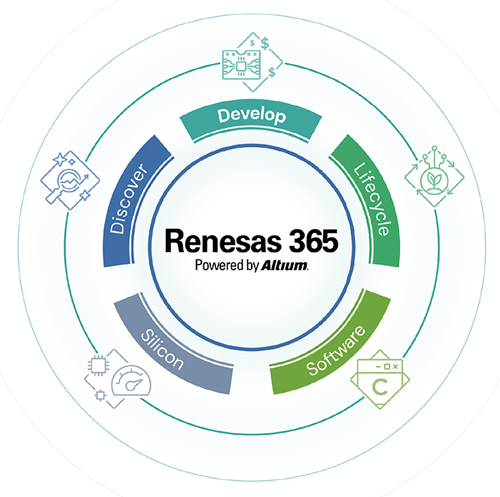

In that spirit, in August of last year, Renesas completed the acquisition of Altium, a global leader in electronics design and collaboration software, following an extensive and productive partnership. The manifestation of that alliance is Renesas 365, Powered by Altium, a first-of-its-kind virtual design environment that liberates engineers by unifying software, firmware, and hardware development workflows to improve efficiency and accelerate design cycles from concept to volume production. Renesas 365 is the next step in the digital transformation of electronics, bridging the gap between silicon and system development. We recently showcased this revolutionary digital platform at embedded world 2025.

I interviewed Ted Pawela, VP and Head of Customer Success, Digital Industries, at Renesas and the former chief operating officer at Altium. We discussed how Renesas 365 combines the best of what the two companies have to offer to create a richer, more dynamic customer experience. As Ted explains, the result is a multi-discipline design platform in which software heavily influences the value of embedded hardware solutions.

D.K.: Ted, can you describe the state of embedded electronics design that sparked the idea for Renesas 365? Where did you see room to improve?

Ted: Renesas and Altium saw that software-defined design needed to do a better job of incorporating microprocessors, microcontrollers, and power components – and not just electronic hardware but mechanical hardware, too. At the end of the day, electronics design and development is a team sport, and yet the systems and tools were generally optimized for a single [hardware] discipline. We saw a need to streamline the development process by enabling people to work together more collaboratively.

D.K.: Within that collaborative framework, the Renesas 365 team quickly recognized the need for contextualization. How does that enhance the design process?

Ted: It comes down to understanding the intent behind the design. Let's say I'm a Renesas field applications engineer. When a customer tells me they need the latest driver for a chip, I can fill the request, but I don't really understand what they're trying to do. The reality is that a lot of requests are made asynchronously through email or voicemail or text or a Slack message. It's much more difficult to give customers what they need without knowing the outcome they're designing for.

Collaboration inside of a company is important, but it extends beyond that. The more everyone involved in the design chain understands the intent behind a design, the better they're able to help each other – and right away, without the need for multiple iterations. In the past, engineers generally lacked that full context. With Renesas 365, we've created a continuous digital thread, not just to share product information but to provide the context as to why the customer is using a particular chip.

D.K.: How does that deeper understanding of the design journey help Renesas' customers?

Ted: It allows us to provide them with what I call application-ready silicon as opposed to leaving the designer to hunt component by component and hope in the end that they're all compatible. Keep in mind, Renesas 365 is much more than a set of reference designs. We're actually transcending collaboration and crossing into co-design.

D.K.: What do you mean by co-design?

Ted: Co-design is a form of guided collaboration that streamlines the design process and makes it faster and less expensive because fewer mistakes need to be corrected.

Say you're building a traffic monitoring system, and you have a PCB, a mechanical sub-system, and embedded software. Typically, these are all designed independently. With Renesas 365, if you make a change to the circuit board that affects the software, then the developer is notified of that change and how it might impact him. The same holds true for the mechanical designer. This keeps them from showing up at a design review meeting and finding out they have to do rework because they weren't notified of the change.

D.K.: Are you finding a receptive audience for this elevated approach to design engagement?

Ted: Yes, and particularly in heavily regulated environments where compliance is important. If a problem occurs, the regulatory bodies responsible for investigating the cause are going to ask a lot of questions about how the chips were designed and tested. So, context is important, not just because it helps us get the design right the first time, but because it establishes an immutable record that documents all of the design decisions.

D.K.: What skills did Renesas and Altium bring together to create Renesas 365, and how is that different from what others may offer across the semiconductor industry?

Ted: Renesas 365, Powered by Altium, is the embodiment of our Digitalization vision. If you look at the portfolios that we each brought to the table, Renesas has the silicon itself as well as embedded software development tools. Altium brings an underlying cloud platform, Altium 365, and tools that are specific to PCB design. That's what enables the whole concept of going from silicon to system.

As for how we differentiate, I've never seen anything like Renesas 365. When you put a 100 percent software company like Altium together with a silicon manufacturer like Renesas, there's no other combination like it. This connection is unique in an industry that has been fragmented for decades now. There is no other single solution available that can thread the design chain from silicon to a final system output. It's not there.

D.K.: Thanks, Ted. As we prepare for the formal Renesas 365 launch in the early 2026 timeframe, we invite customers, prospective customers, and other interested parties to request more information and receive updates on progress and milestones. For more information about Renesas 365, please visit: renesas.com/renesas365.