Due to recent CO2 emission regulations, the electrification of automobiles has increased rapidly. There are two types of electric powertrain-equipped automobiles: HEVs (Hybrid Electric Vehicles) and BEVs (Battery Electric Vehicles), and they are both called xEVs. HEVs have a powertrain system that uses both an internal combustion engine and an electric motor. HEVs include FHEVs (Full Hybrid Vehicles), MHEVs (Mild Hybrid Vehicles), and PHEVs (Plug-in Hybrid Vehicles). They are also called xHEVs. Since xHEVs still emit CO2 from the internal combustion engine, there is an incentive to shift from xHEVs to BEVs that are pure electric, CO2-free vehicles.

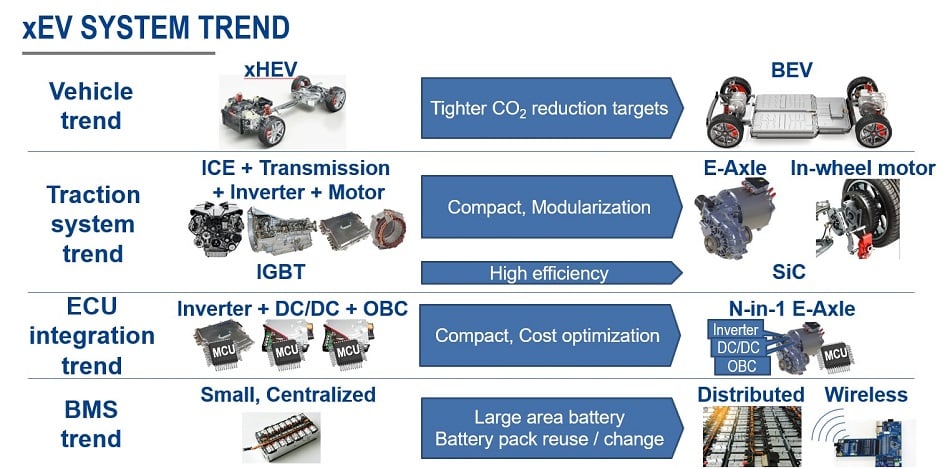

Figure 1:xEV system trends

With the transition from xHEVs to BEVs, system changes are expected as shown in Fig. 1. Complex traction systems with an internal combustion engine, a transmission, an inverter, and an electric motor are merged into E-Axle, a module that integrates the inverter, electric motor, and reduction gear. In addition, BEVs require more efficient IGBTs and SiC MOSFETs to meet the power efficiency requirements. While BEVs require ECUs, including inverters, DC/DC converters and on-board chargers (OBC), there is a growing need for BEVs to integrate DC/DC and OBC into the E-Axle, a trend called N-in-1 or X-in-1.

Although a small battery is sufficient for xHEVs, BEVs need a large battery that spreads over the floor. A small battery in xHEVs requires only a short total length of wiring to monitor each battery cell, but a large battery requires a large amount of wiring, so a wireless battery monitoring system (BMS) is also desired. Renesas is developing solutions based on these trends.

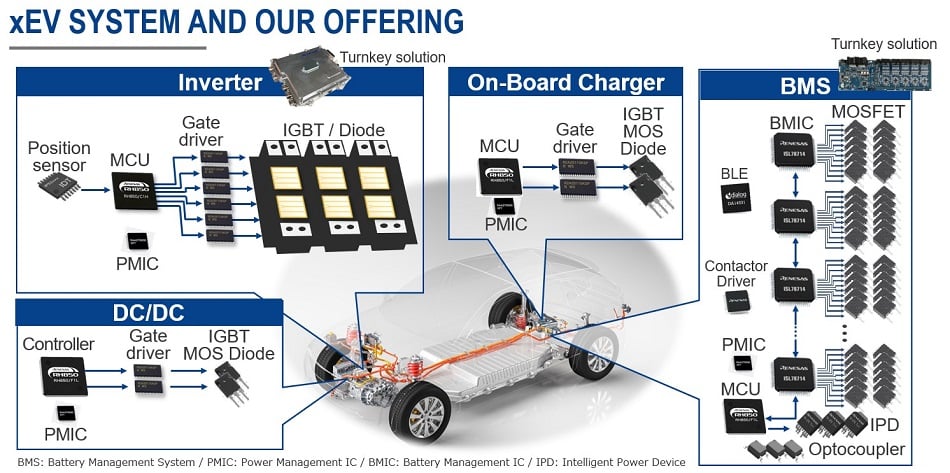

Figure 2:xEV system

Figure 2 shows an overview of the xEV ECU configuration. xEVs mainly consist of an inverter, a DC/DC converter, an OBC and a BMS. The inverter, DC/DC converter, and OBC consist of a microcontroller (MCU), a power management IC (PMIC), gate drivers, power devices such as IGBTs or SiC MOSFETs, and a position sensor. The BMS consists of a MCU, a PMIC, battery monitoring ICs (BMIC), IPDs, photocouplers, etc. Wireless transceivers such as BLE are also required in wireless BMS.

Since Renesas offers all of these products, it allows us to anticipate system trends and propose solutions at the system level.

Figure 3:Renesas’ inverter solution

As more BEVs become available, they require a huge amount of high-performance IGBTs and SiC MOSFETs. Renesas is investing in the development of new generation AE5 IGBTs to improve performance. In addition, we are also investing in the Kofu factory in Japan to start mass production of 12-inch IGBTs. Since the E-Axle is getting smaller and more highly integrated, and the price competition is getting tougher, reducing BOM is important. Renesas is developing a gate driver unit (GDU) with a built-in flyback power supply that greatly reduces the external BOM, contributing to a reduction of BOM cost and the PCB area. We are also providing inductive position sensors (IPS) that are ideal for E-Axles in which PCB is integrated into a motor module. It contributes to reducing the volume, weight and cost compared to conventional resolvers. We are developing an N-in-1/X-in-1 solution that controls not only inverters but also DC/DC converters and OBC with a single MCU.

Renesas is building inverter systems using our MCUs, PMICs, GDUs, IGBTs, and IPS, and providing customers with a turnkey solution to help shorten development time and reduce development costs. In addition, we have started developing a turnkey solution for N-in-1 E-axle, to respond to the trend of both E-axles and N-in-1/X-in-1 integration. We are providing proven solutions at the system level to meet the increasingly stringent requirements for size and BOM reduction.

Figure 4:Battery Management System

We are providing a best-in-class high accuracy BMIC (measurement error of ±2mV or less in the cell voltage range and temperature range required for automotive applications) and a BMS turnkey solution using the BMIC. The turnkey solution helps reduce development, especially for customers in emerging countries. To prepare for the future of wireless BMS, we have proof-of-concept (PoC) solutions for wireless BMS. One demonstration has a wireless transceiver per multi-cell battery pack, and another demonstration has a wireless transceiver for each cell, which is the ultimate wireless BMS. Renesas' BLE transceiver contributes to the competitiveness of wireless BMS with its small size, low power, and low BOM cost.

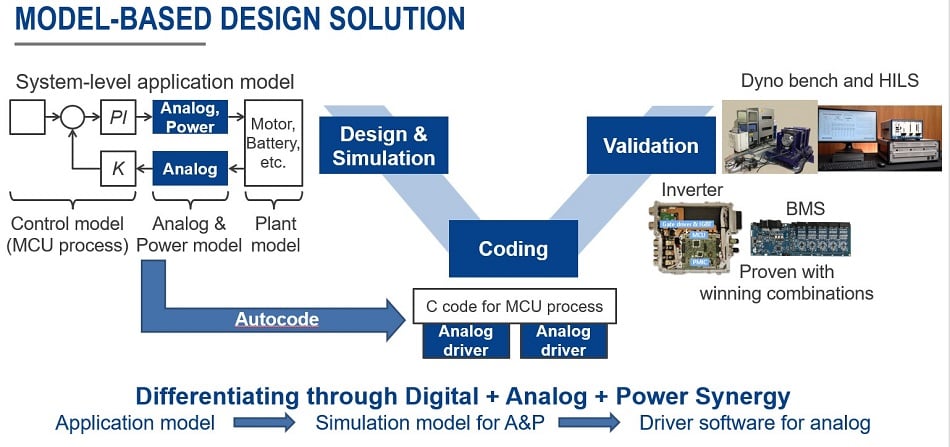

While reference designs shorten the time and cost of developing hardware, reducing development efforts for software is also a major challenge. Renesas provides software (C source code) required for inverters and BMS and a software development environment using model-based design (MBD). We provide simulation models that include 1) a control model processed by MCU software, 2) analog and power product models, and 3) a plant model based on simulation models such as motors or batteries. Customers can use our model as is or modify it to achieve the desired operation by editing our controller model on MATLAB. Once the simulation is completed, customer can automatically generate C code using the Autocode function of MATLAB. MCU peripherals, analog and power products are replaced with device driver software provided by Renesas, and they are integrated into the C code generated by the Autocode. Renesas validated the software generated by the Autocode using our inverters or BMS reference design, running them in a dyno bench or a HILS environment.

Our solution can 1) enable system-level simulation in early stages of design, 2) eliminate the need for hand coding, and 3) eliminate human errors during coding. These eliminate the need for debugging and backtracking, thus making software development more efficient.

Renesas has a broad portfolio of products, including MCUs, analog and power products, and contributes to reducing customer R&D efforts through one-stop solutions and technical support.