In recent years, the requirements for human-machine interface (HMI) devices have become more sophisticated. Operability, response speed, high-resolution displays, rendering of 3D graphics, etc., must satisfy users who are familiar with smartphone operations.

Microprocessors (MPUs) are essential for the development of such high-performance HMI devices, but developing a custom board with an MPU requires a lot of financial and manpower resources. Even though large projects may have access to these resources, small and medium-sized projects will often not have access to sufficient resources. In addition to resources, it is also required to bring products to market in a timely manner.

For developers facing these challenges, the system-on-module (SoM) and single-board computer (SBC) embedded with the RZ family MPUs are here to solve all your challenges.

Figure 1. SoM Image

SoM is a board that has major components such as MPU, main memory, and power supply pre-installed. It does not have connectors for direct connection to peripheral devices, and connectors are placed on a carrier board that is prepared separately. Users need to create their own carrier boards, but they can freely place interfaces with peripheral devices.

Figure 2. SBC Image

The SBC contains not only major components such as MPU, main memory, and power supply but also connectors to peripheral devices, all on a single board. In contrast to SoM, it is possible to connect to peripheral devices without preparing a carrier board. However, it is difficult to add connectors.

There are two main advantages to using SoMs and SBCs.

Firstly, there is no need to design the PCBs. To develop a custom board, users need to design the timing with the system clock and DRAM, which are very difficult to route and simulate the board with noise. On the other hand, board vendors who developed SoM and SBC have already verified these issues in SoM and SBC, so users do not need to work on these difficult designs.

Figure 3. PCB Design Image

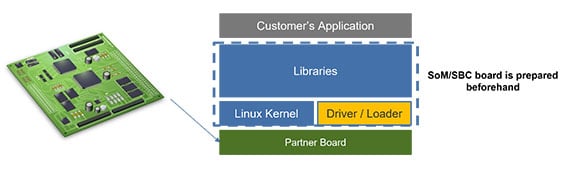

The second advantage is that custom board support package (BSP) development is not required. Since the BSP is provided by the board vendor, users can focus on developing applications to differentiate their products.

Figure 4. BSP Image of SoM/SBC

These two advantages reduce costs and resources related to board and software design and shorten development time. This shows that SoM and SBC are solutions that can reduce costs, resources, and development time.

Although SoMs and SBCs offer the above advantages, it would be difficult to use without a board that has functions, performance, and interfaces meeting the user's needs. The Renesas RZ family MPUs provide various functions, performances, and I/F. In addition to the hardware expertise, there are many mass-production-ready boards from partners that incorporate these MPUs.

Visit Renesas RZ Partner Ecosystem Solutions and find the right board for your development.