Challenges Facing Evolving E/E Architecture Development

As software has come to create new value for vehicles, user application software has become larger and more complex. Efficient software (SW) development methods have become an essential requirement for advanced vehicle development.

With the evolution of E/E architecture, more and more devices tend to be installed, and for SW verification with SW already installed in these devices, interconnectivity with each other is essential. If each actual device is available and can be interconnected, interconnected SW verification can be performed, but issues cannot be detected until the final stage of development, resulting in significant rework.

In addition, a simulation environment can be used to start SW development at an early stage. However, the simulation environment for a single device cannot be interconnected, and system-level verification with multiple devices working together is not possible.

This makes it difficult to ensure quality because verification is based on complex scenarios that are assumed .

Overview of Multi-Device Co-Simulation Environment

Multi-Device Co-Simulation Environment

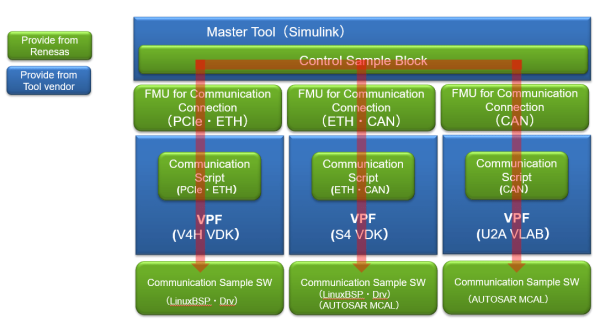

Figure 1 shows the configuration of the multi-device co-simulation environment.

Renesas proposes a multi-device co-simulation environment that enables devices to be interconnected and software development to begin without the need for actual devices.

- Function Mockup Unit (FMU) (*2) and control sample block for easy connection of each Virtual Platform (VPF) via master tool (*1)

- Communication script to connect FMU and VPF

- VPF (*3) simulates the operation of each actual device

- Communication sample SW operating on interconnecting VPFs

By using these, interconnected software development can be started before the actual device is available. Since software developed on VPF also runs on the actual device, software development and verification on the actual device can be conducted without delay after obtaining the actual device. This enables early development of interconnected SW and early detection of problems. (Master tools and VPF must be obtained by the user.)

(*1) Master tool: Tool to coordinate and synchronize the operation of each VPF

(*2) Function Mockup Unit (FMU): A library for connecting tools according to the Function Mockup Interface (FMI), a model IF for connecting different tools. By importing from the master tool, interconnections can be made within the master tool.

(*3) Virtual Platform (VPF): A simulator for SoCs and MCUs that can execute SW similar to real devices.

Measures for Connection Between CAN Models

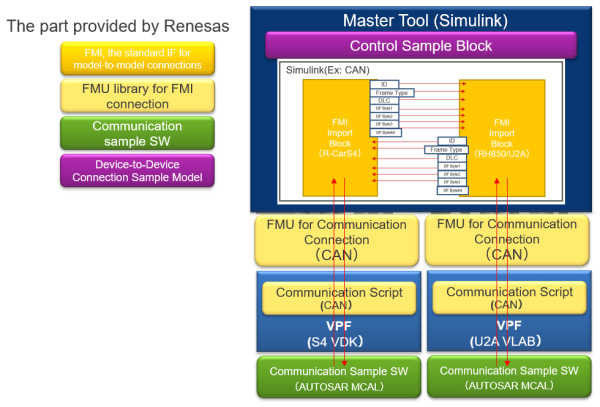

Figure 2 shows how to realize CAN communication between models connected by FMI.

The FMI defines what types and timing of data transmission and reception are possible, but there is no definition of specific connection specifications. It is left to the user to determine which parameters and how to connect, and it is necessary to define the connection specifications in the FMI.

For this reason, the cooperative simulation environment for multiple devices has developed CAN connection specifications for connection between FMI import blocks as shown in Figure 2. Models with an FMI that conform to this specification can be connected to each other.

Development Status of Cooperative Simulation Environment for Multi-Device

This time, we introduced the cooperative simulation environment for multi-device with R-Car S4 and RH850/U2A connected via CAN.

Please refer to the Introduction of Virtual Platform Co-simulation demo video recorded of actual operation for easy reference.

This solution proposal enables the use of an environment that enables interconnected SW development without the need for actual devices and enables shift-left vehicle SW development. By using the cooperative simulation environment for multi-devices, it will prevent bugs before they happen, shorten the overall testing time, and improve software quality.

In the future, R-Car V4H and plant models such as motors will be connected, and a wider range of devices will be interconnected. Preparations are planned for use in software development and system studies.