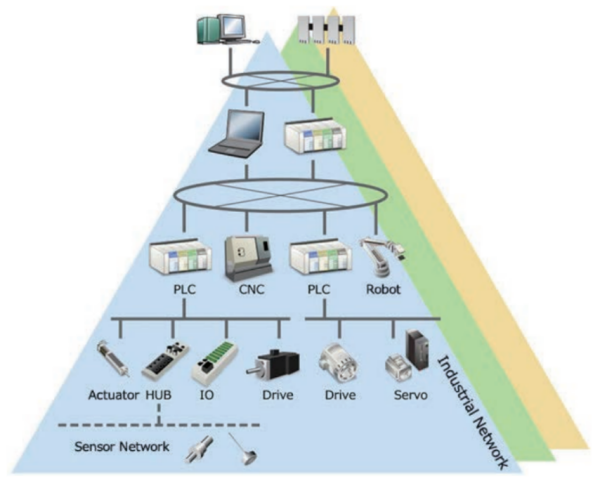

Effective communication is the lifeblood of efficient and productive operations in today's rapidly evolving industrial landscape. Industrial field communication (IFC) facilitates data exchange and real-time decision making during digital transformation.

IFC is driven by operational efficiency. It allows real-time monitoring, remote control, and predictive maintenance, reducing downtime, increasing productivity, and optimizing resource utilization. Field communication combined with advanced data analytics and machine learning techniques allows businesses to make data-driven decisions and achieve operational excellence.

This study provides a comprehensive review of IFC's market trends, protocols, uses, benefits, and developments.

The IFC market has experienced substantial growth, with a market size of USD 13.18 billion in 2021, as per Grand View Research. It is projected to grow at a CAGR of 11.8% from 2022 to 2028, fueled by the rising adoption of Industry 4.0 technologies like IoT and cloud computing, which are driving the demand for IFC solutions in various industries.

IFC solutions are gaining popularity, especially in process industries such as oil and gas, automobile, FMCG, etc. for use cases like real-time monitoring, process optimization, and predictive maintenance. The market for IFC is expected to grow further due to increasing demand for industrial robots and automation. Ethernet-based communication solutions are also expanding in the IFC sector, providing high-speed data transmission, real-time monitoring, and remote diagnostics required by modern industrial applications.

IFC is experiencing growth due to the rising acceptance of Industry 4.0 and automation in various industries. The utilization of digital twins for the safe monitoring of smart production activities is likely to further boost the industrial communication market. However, the lack of standardization in communication protocols and interfaces may hinder the adoption of different industrial communication technologies.

In the realm of industrial field communication (IFC), fieldbus areas like Modbus, CANopen, PROFIBUS, and CC-Link play pivotal roles in achieving seamless communication between devices and control systems. Similarly, EtherCAT provides high-speed real-time communication, catering to demanding automation applications.

| Protocol | Master-Slave | Peer-to-Peer | Deterministic | Latency | Bandwidth |

|---|---|---|---|---|---|

| Modbus | Yes | No | No | High | Low |

| CANopen | Yes | Yes | No | Low | Medium |

| PROFIBUS | Yes | No | Yes | Medium | High |

| CC-Link | Yes | No | No | Low | Medium |

| EtherCAT | Yes | No | Yes | Low | High |

As a leading provider of industrial communication solutions, Renesas' industrial communication solutions allow devices and systems on a production floor to communicate seamlessly. Industrial Ethernet and Fieldbus solutions from Renesas enable clients to migrate to Ethernet and current communication technologies. For real-time control and monitoring applications, these technologies offer secure connectivity, fast data transfer, and minimal latency.

Industrial communication solutions from Renesas cover a wide range of industrial needs. The RL78, RX, RA, and RZ solutions offer high-performance communication for industrial robots, factory automation, and building automation.

Renesas' RX72M Network Solution is an advanced offering designed to deliver high-speed industrial communication capabilities. This scalable and flexible platform supports a range of communication protocols, including EtherCAT, PROFINET, EtherNet/IP, Modbus, and CC-Link. With real-time communication capabilities and low latency, the RX72M solution is well-suited for applications that require precise control and monitoring. It offers industrial communication solutions that accommodate existing architectures and facilitates the transition to Ethernet where needed, and high-performance communication capabilities to meet industrial demands.

Renesas offers a wide variety of Industrial Field communication solutions based on features-rich MCUs, MPUs, and other critical system components. Our solution suite includes best-in-class communication components for all leading industrial communication protocols such as EtherCAT, PROFINET, EtherNet/IP, Modbus, CC-Link, and more. Seamless real-time communication is at the core of all Industry 4.0 and IIoT implementations offering exciting new opportunities for all stakeholders. We invite you to join us on this exciting journey to help obtain accurate control, monitoring, and networking of a wide range of industrial applications.

Check out Factory Automation, Industrial Ethernet & Fieldbus, and RX72M Network Solution to discover more about a whole host of Renesas-based Industrial Communication solutions.

News & Additional Resources

| Title | Type | Date |

|---|---|---|

| Industrial Ethernet and Fieldbus | Page | Jun 3, 2023 |

| RX72M Network Solution | Page | Jun 23, 2020 |