In general, nearly 100% of the energy consumed in residential and commercial, 75% in transportation, and 70% in industrial applications, is discharged as heat into the global environment1. Recycling this dissipated heat is crucial to help address rising global warming and climate change concerns. As well, energy harvesting is environmentally friendly and provides efficient energy management while also extending battery life operation for years without a replacement. The energy harvesting system market is projected to grow from USD 485 million in 2020 to USD 775 million by 20252. Moreover, in an era of the Industrial Internet of Things (IIoT), wirelessly transmitting industrial process data to central monitoring stations allows for remote monitoring of industrial data such as the flow rate, temperature, gas, humidity, etc. This helps enable predictive maintenance in industries where equipment is difficult to access, and long wire deployments are not practical. The IIoT market is expected to grow from USD 77.3 billion in 2020 to USD 110.6 billion by 20252.

Renesas has come up with a system that leverages the heat these industrial processes generate and, with the help of the Energy Harvesting System (EHS), can help companies create a recycling system to convert this heat into reusable electrical energy (figure 1). This is a self-sustainable system used for monitoring remote industrial processes where dissipated heat can be recycled into electrical energy and can then be used to power the electronics system used for monitoring and transmission of process data. A prime usage example is for industrial pipes carrying hot fluids or gases in them.

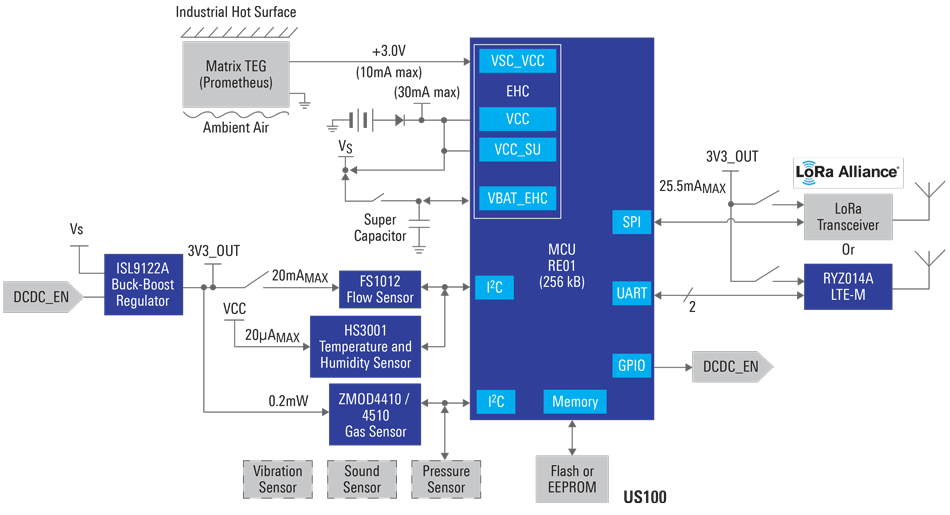

The system uses a thermoelectric generator (TEG) in contact with industrial pipes for the conversion of dissipated heat to electrical energy to power the electronics in the system. The energy harvesting control circuit utilizes the RE01-256KB MCU ensuring ultra-low power consumption. The RE01-256KB MCU is a 64MHz Arm® Cortex®-M0 based microcontroller using the world’s best ultra-low power Silicon On Thin Buried Oxide (SOTB) process technology that makes it ideal for energy harvesting applications eliminating the need for battery replacement/maintenance. Back-up energy is provided through a battery and supercapacitor for periods when no harvesting is possible.

Gas or Liquid flow rate data can be sensed using FS1012 which is a MEMS mass flow sensor module measuring the flow rate utilizing thermopile sensing, which provides an excellent signal-to-noise ratio. Relative humidity and temperature are sensed using the HS3001 which is a highly accurate, fully calibrated MEMS-based sensor. It features proprietary sensor-level protection ensuring high reliability and long-term stability. Both have fast response times to improve accuracy and reliability along with consuming low power to improve energy efficiency. Outdoor and indoor air quality can be monitored using Renesas’ ultra-low power gas sensor modules, the ZMOD4410 and ZMOD4510. The provided firmware enables different features based on traditional and machine learning algorithms with embedded artificial intelligence (AI). This is used to determine the Total Volatile Organic Compounds (TVOC) concentration, Air Quality Index (AQI) rating, and estimated carbon dioxide (eCO2) level.

The sensor data can be sent to far-off central monitoring stations using the RYZ014A module which is a low power all-in-one, single-mode LTE category M1 module with worldwide deployment and roaming capability. The module not only includes the modem system but is a complete platform and includes a transceiver, RF front-end, and other interfaces with the complete LTE stack running inside the RYZ014A module. Alternatively, data transmission can also be done using the onboard LoRa transmitter with mesh network which ensures wide-range transmission with ultra-low power consumption. The system architecture is optimized for balancing power in the system by interleaved operation of the data collection and data transmission networks with the help of multiple switches.

Reference 1: https://environmentalsystemsresearch.springeropen.com/articles/10.1186/s40068-020-00169-2#ref-CR1

Reference 2: https://www.marketsandmarkets.com