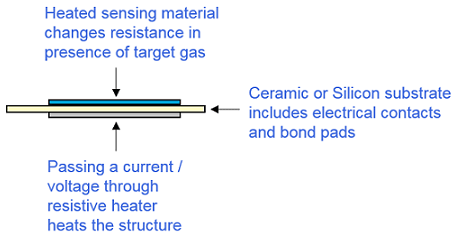

As anyone who has worked with them knows, not all sensors are made the same. There is a wide variety available on the market for the detection of industrial gases. MOx sensors, sometimes called chemiresistive sensors, are well known for their ability to offer affordable, reliable performance in harsh applications. However, each MOx solution has many integral aspects that support optimized performance. The substrate used, the applications circuitry and the Metal Oxide (MOx) material are several critical components of the sensor module.

MOx materials work on the principle of gases influencing the free charge carrier concentration in the MOx material. Through the adsorption and desorption of gas molecules, the change in resistance provides a distinctive analog signal. This signal is then converted into a digital equivalent in which specific gases are quantified.

The Importance of MOx Stability

The surface interaction on the MOx surface includes both physisorption and chemisorption and is influenced by several factors, including operating temperature, gases present, oxygen concentration, and MOx surface geometry. The reaction between gas and oxygen and the oxygen equilibrium of the surface transfers the charge, and subsequently, resistance is measured.

The "recipe" for MOx material composition and structure is developed and perfected over years of experience, and performance is highly dependent on its fabrication method. Careful selection of materials and operation methods, in conjunction with a deep understanding of applications and system engineering, result in sensors that are well-suited for use in consistently reliable measurement of target gases. The ability to optimize the signal-to-noise ratio by reducing drift and response is influenced by everything from the recipe to environmental contaminants and is heavily dependent upon the methods used for material fabrication, as well as with operating temperature.

Data Tells the Story

When evaluating sensor performance and stability, nothing beats the test of time. A review of any sensor manufacturer’s datasheets and supporting collateral should outline how the sensor behaves in the presence of target gases, as well as the influence of environmental variables. Review how claims related to sensor life and stability are measured and supported. MOx materials and appropriate deposition methods that have been in use for more than 10 years ensure the production of the most reproducible and reliable sensors that will enable you to safely predict the future performance of your products. Demand the supporting data as it will be a critical factor in ensuring your success in the market.

To learn more about Renesas’ gas sensor portfolio built on more than 10 years of perfecting the ideal MOx composition, visit renesas.com/gas.