As we outlined in our last blog (Industrial Networking in Industry 4.0 and Evolution of Industrial Networking and Best Practices), within the framework of Industry 4.0, stakeholders have the ability to optimize facilities and increase efficiency thanks to the interconnection of industrial equipment and enhanced computation. Industry 4.0 is characterized by Interoperability (such as IIoT), information transparency (digital plant models: Virtual copy of physical world), technical support (the ability of cyber-physical systems to support humans by executing various tasks), and decentralized decision-making. IIoT allows devices to be connected, creating a virtual copy of real-world data that allows operators to visualize/analyze processes and make decisions to complete tasks autonomously. Industry 4.0 integrates intelligent systems, machines, and people and changes manufacturing processes providing real-time data to factory floor workers by exchanging data between field devices. However, there are various challenges associated with factory floor interconnectivity on the path to achieving Industry 4.0.

Whether you're talking about the Internet of Things or Industrial 4.0, connectivity is an essential part of both. The ability of IIoT devices to connect with gateways, apps, servers, routers, and other IoT devices is highly reliant on networks. IoT devices are only able to carry out the tasks they were intended for because they are able to communicate with one another and send and receive data. In other words, IIoT enables Machine-to-Machine (M2M) communication and makes manufacturing facilities smart and digitalized.

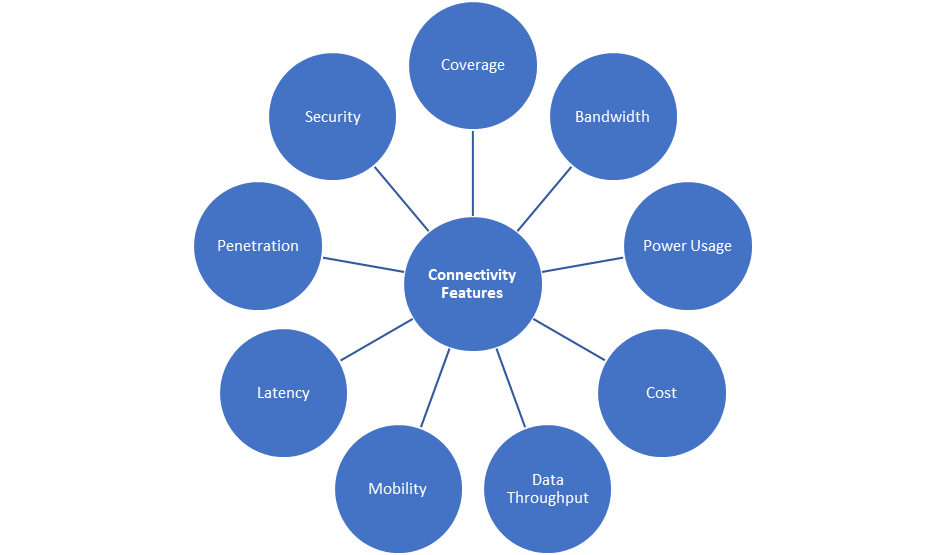

Industrial network connectivity solutions for IoT devices are wide and diverse. Finding the best solution for connectivity applications will always be challenging. There may be additional aspects that become more crucial depending on your device specifications, deployment setting, and required features (refer to Figure 1).

Figure 1. Industrial Networks connectivity features

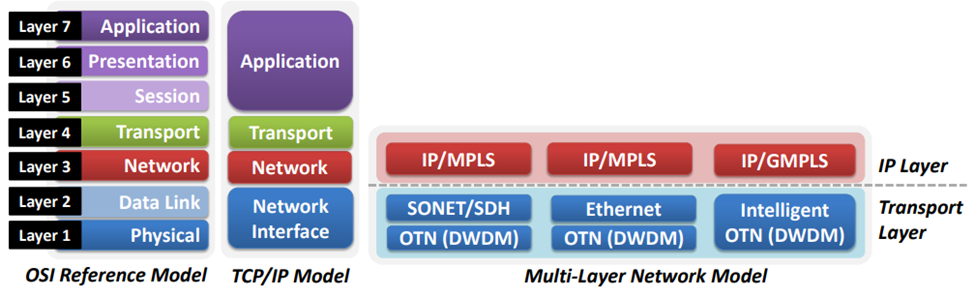

Figure 2. Comparison of TCP/IP and Multi-Layer Network Model to Traditional Open Systems Interconnection (OSI) Reference Model (Martinez et al. 2014)

The exponential growth of Internet traffic in industrial automation or IIoT is shortening the life cycle of core networking technologies. The industry has made rapid progress in data and control planes to meet traffic demand. However, there are still many challenges remaining to better manage device connectivity and communication. This stems from segmented competencies in managing multi-layer infrastructures. Current industrial networks are multi-layer, with IP routers and other network nodes where each layer is made up of devices from different vendors with their own (proprietary) network management system (NMS). In practice, the lack of widely accepted interoperability mechanisms has isolated these proprietary systems. As a result, network operation and maintenance tasks are becoming more complex, leading to function duplication, higher OPEX, and delays in multi-layer provisioning coordination. Figure 2 shows the mapping between OSI, TCP/IP, and a multi-layer network where a carrier network's layering model, represents different deployment scenarios (from left to right). Intelligent Optical Transport Network (OTN) refers to an optical network with advanced control planes. However, network management for a complex floor lag behind carriers' expectations. Network management includes the Operation, Administration, Maintenance, and Provisioning (OAM&P) functions needed to monitor, configure, interpret, measure, and control the network and its services. Network Management has long been a goal of carriers as a way to improve service monitoring, resource administration, operational costs, network performance, fault recovery, and control and security. Proper network management creates a secure, reliable, dynamic system that can detect and react to critical scenarios that affect network performance.

For quite some time now, convergence and deregulation have been reshaping the network industry's landscape. Contrary to expectations, these trends did not simplify the infrastructure and scenario, resulting in an explosion of networks, services and applications, operators, and service providers. This heterogeneity demands interoperability of networks and applications among operators. To set a foundation for critical command, control, and intelligence of network connectivity, network interoperability has become a major challenge for operators. Network interoperability usually refers to the functional interworking of network services across multi-vendor, multi-carrier interconnections working under stressful or even normal conditions, as per the applicable standards and required specifications. Network interoperability becomes indispensable in order to achieve end-to-end connectivity. The more diverse networks exist, the greater becomes the need to ensure that they can interoperate to make end-to-end communication possible. Other than safety and security aspects, there are the following concerns associated with resources and costs:

- Development resource and time: Adding features for network compatibility requires effort and money. Also, Interoperability testing and acceptance consume effort and time.

- LTM (Long Term Maintenance): Network/application modalities increase procurement expenses. Also, managing interface configuration adds complexity and cost.

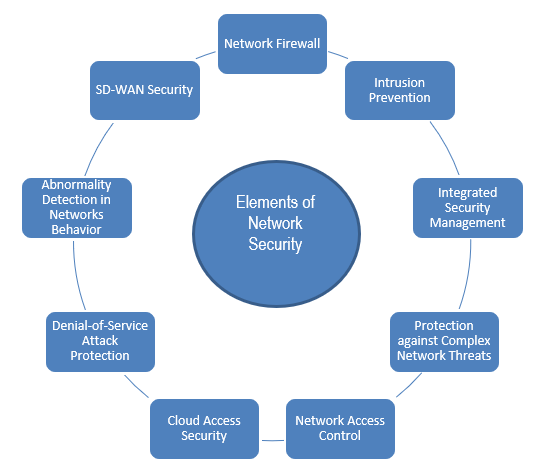

Network security helps to protect a computer network's data. Successful network security strategies use multiple security solutions to protect users and organizations from malware and cyberattacks. A network consists of computers, servers, and wireless networks. Attackers can target any of these devices. Network security uses software, hardware, and software as a service. As networks become more complex and businesses rely more on them, security becomes more important. Network security is enforced using a combination of hardware and software tools (refer to Figure 4). Network security prevents unauthorized access to and within networks. A security official or team determines strategies and policies to keep an organization's network safe and compliant with standards and regulations. All network users must follow these security rules. Every network point where an authorized user can access data can be compromised by a malicious actor or user carelessness or mistakes.

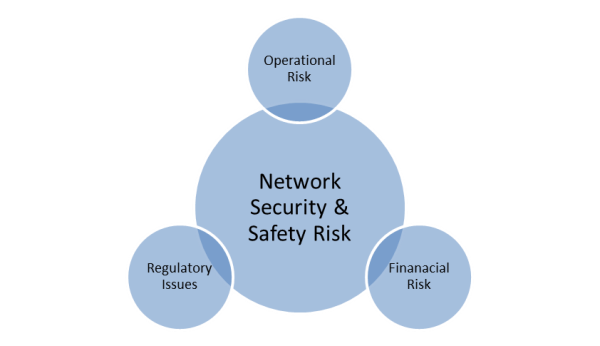

Figure 3. Risks associated with Network Connectivity

Figure 4. Elements of Network Security

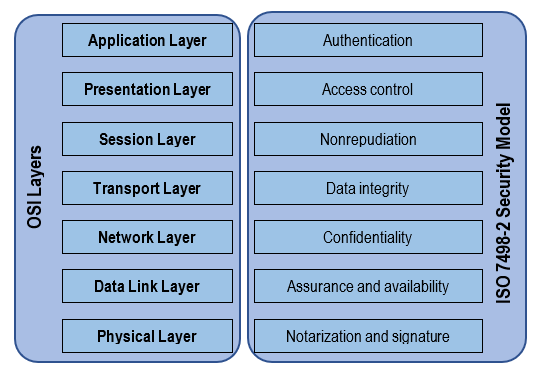

The Open Systems Interconnection (OSI) model depicts the various layers present in a network. When information travels from one device to another, it goes through these layers, each of which can be vulnerable to a unique set of cyberattacks. Therefore, the security of the network depends on the security of each layer of the stack individually. As shown in Figure 5, each layer of the Open Systems Interconnection model corresponds to a specific facet of network security described in ISO/IEC 7498-2.

Figure 5. ISO/IEC 7498-2 Security Model for OSI Layers

Renesas’ Winning Combinations are engineering-vetted designs that provide a solid foundation for customers' own design concepts, shortening product development times and reducing total risk. Currently, more than 350 Winning Combinations are available from Renesas for use by a broad spectrum of customers and industries. These expert designs showcase Renesas' complementary product portfolios of Embedded Processing, Analog, Power, and Connectivity. For example, Renesas provides a wide range of devices and solutions in the connectivity area, including being the serial switching market leader due to its advanced PCI Express® and Serial RapidIO® switches. In addition, Renesas' dual protocol transceivers, voltage level translators, I2C Buffers, and RS-232/RS-485/RS-422 devices support high-speed data transfer and configurable options. Bluetooth Low Energy (LE), LoRa-based solutions, and Sub-GHz wireless communication solutions are just some of the wireless connectivity products offered by Renesas. In addition, the company provides complete Clocking/Synchronization solutions and modules that assist customers in building networks that connect devices and systems for the connected world. The diverse range of secure wired/wireless networking solutions makes it easier to connect elements and functions in all types of factories. Developing a secure product requires a comprehensive set of security solutions. Renesas Secure – IoT, which includes unique MCUs, valuable certifications, and customizable solutions, guides design engineers through the design and implementation of a secure, connected application, beginning with basic security concepts and progressing to advanced topics such as key handling and cloud connectivity, and finally mass production and secure firmware updates. By providing a platform-based approach to security that takes advantage of the latest breakthroughs in hardware and software to deliver in-depth, comprehensive protections with multiple layers of security, Renesas aids embedded developers in meeting the challenges of securing designs. Device security technology support for critical assets on the silicon, network security support for confidentiality and integrity of data transferred over communication channels – these are just a few examples of the ways in which Renesas helps its customers ensure the root of trust of factory automation equipment and industry network connections. Throughout the product's lifecycle, our solutions safeguard intellectual property and permit scalable production.

Figure 6. Renesas Secure-IoT Concept

Implementations of Industry 4.0 and the Industrial Internet of Things (IIoT) are required to have a core prerequisite that guarantees uninterrupted real-time communication. At Renesas, we offer a variety of MCU and MPU devices coupled with all the necessary building blocks to develop a wide range of networking solutions covering leading industrial communication protocols, including PROFIBUS/PROFINET, EtherNet/IP, EtherCAT, Modbus, CC-Link, etc. Our device solutions, e.g., RA, RX, RL78 MCU, or RZ MPU-based solutions, come with a dedicated suite of software support enabling the design and engineering team to focus on the application development to achieve quicker time to market. Click Factory Automation, Industrial Ethernet & Fieldbus, Industrial Network, RX72M Network Solution to discover more about a whole host of Renesas based Industrial Communication solutions.

Related blog posts:

[1] Industrial Networking in Industry 4.0

[2] Evolution of Industrial Networking and Best Practices