Quality

Our Quality Policy

At Renesas we prioritize safe and secure manufacturing and have established a “Quality Policy” aimed at maximizing customer satisfaction and assuring the highest level of confidence in our products and services. In accordance with this policy, we continuously endeavor to improve quality in all aspects of our business, in order to respond quickly to customer requirements with suitable, high-quality and highly reliable semiconductor products and solutions.

Quality Policy

We aim to deliver customer satisfaction and enhance society by providing highly reliable and high-quality products and services.

We abide by the following principles in all stages of our business activities—including sales, design, development and manufacturing— in accordance with our corporate quality management system.

We will:

- Comply with all applicable legal and regulatory requirements

- Enhance product safety and trust

- Commit to continuously improve the quality of products and services

- Strive to continually improve our quality management system

Product Safety Policy

We commit to the full realization of our Quality Policy and maintaining product safety in observance of relevant laws, environmental regulations, and standards, and deploying initiatives aimed at advancing product safety. We base our actions on the Basic Product Safety Policy shown below in order to advance our goals of safe and secure manufacturing.

Basic Product Safety Policy

- We observe in-house and external laws and regulations, technical standards, industry standards, etc., related to product safety and establish the appropriate safety levels that our products must fulfill.

- We maintain safety through safe design practices aimed at product safety in the true sense.

- We conduct safety inspections to confirm safety.

- Should an accident occur or should there be fears of such an occurrence, we will endeavor in good faith to provide support for our customers.

To maintain the safety of our semiconductor products, it is critical to ensure that when incorporated into customers’ finished products, our semiconductors can be used safely, that they exhibit high tolerance for high temperatures and resistance to combustion, and that they impose minimal environmental impact. In our resin mold semiconductor products, we only use resins that have been confirmed for flammability under the UL 94 standard* in order to ensure high tolerance for high temperatures and resistance to combustion. In addition, we perform assessment inspections that evaluate products in terms of both safety and environmental impact in order to reduce the environmental burden at the disposal stage. Furthermore, care is taken in a broad range of aspects to ensure that our semiconductor products can be used safely, including consideration of product specifications, efforts to supply accurate technical information via product documentation, etc., and provisioning information on compliance with environmental regulations.

* UL 94 standard: A product safety standard established by the American certification organization formerly known as Underwriters Laboratories that indicates the degree of flammability of materials by subjecting plastic devices or components to product material flammability tests.

Promotion System

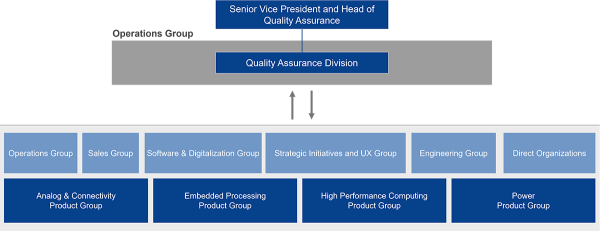

In order to respond promptly to customer requirements, the Quality Assurance Division at Renesas’ Toyosu headquarters plays a central role and collaborates with responsible departments across all Renesas Group sites for quality related functions at sites throughout the Group to swiftly respond to customers’ claims, identify customer complaints rapidly and prevent recurrences of issues.

To assure across-the-board compliance with quality guidance regulations, the Quality Assurance Division has been established as an organization independent from the business and production units, enabling it to prioritize the safety and peace of mind of customers in its actions.

Quality Governance System Conceptual Diagram

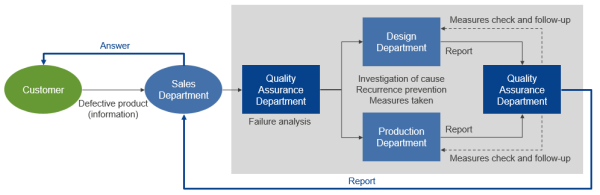

Renesas Group Global Investigation Sequence for Defective Products

When defects are recognized in a product after shipment, efforts to both determine the cause and to correct it are implemented with guidance and support from the Quality Assurance Division , which directly reports to the CEO. In addition, Quality Assurance Division have been established in our primary business regions (Japan, China, North America, and Europe) in order to respond promptly to reports of defects from global customers that contacted us by carrying out investigation and analysis as quickly as possible.

The Quality Assurance Division is tasked with tracking the accurate details of defects reported by customers, assessing their impact, and promptly and accurately making reports of the facts to top management, according to the risk potential. When retroactive measures are deemed necessary in the case of products that are already being shipped, the Quality Assurance Division notifies customers immediately and arranges appropriate measures such as product recalls. From 2019 to 2023, we have no history of product recalls to the market.

Defective products are examined using an array of measurements and analysis equipment to identify the location of faults and their root causes. Then, based on the results of the investigations, the Quality Assurance Division consults with the design, production, and other related departments, takes necessary corrective measures, and reports investigation results to customers as needed. They also trace these processes to ensure they are carried out with the appropriate timing and constantly monitor them as key performance indicators. Finally, laws, regulations, and in-house rules covering markings and labeling related to the quality and safety of products and services are strictly observed.

Quality Management System

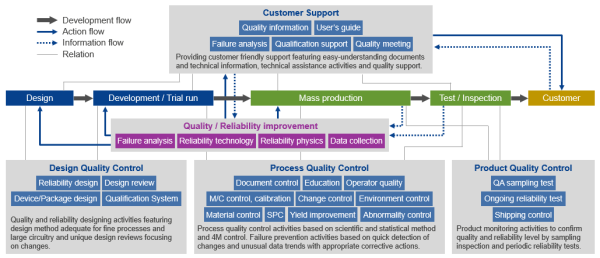

As part of our Quality Policy, we installed a Quality Management System based on the ISO 9001 and ISO/IATF 16949 standards. “Building-in quality” from the design stage, backed by reliability technology, is the fundamental principle under an integrated quality assurance and management regime backed by reliable technology that extends from product planning through after-sales service.

Development Process

We continue to advance design and testing procedures that support the trends toward products with shrinking design rules and larger-scale circuits, as well as ever more sophisticated evaluation technology. Design review methods that focus attention on points of change have been incorporated into gate reviews that take place at each major development process. In-house regulations and guidelines have taken root in the design process at a global level and technology for improving quality has been standardized as we work to improve the quality of design process management.

Manufacturing Process

In the quest to realize stability in manufacturing, efforts to improve quality through 4M (man, machine, material, method) management proceed alongside efforts to build-in quality through scientific process management and improvement efforts at the production sites, which are implemented globally. In addition, thorough product quality management efforts include initiatives to prevent the outflow of defects through early detection and correction of faults.

Support Process

We work to boost the quality of the support we provide so that customers can use our products with confidence. These efforts encompass all processes from system development by the customer through distribution and maintenance, and include the provisioning of product information, solution support, and responses to customer inquiries.

Based on the Quality Policy, we set new quality targets each fiscal year. Continuous efforts are made to improve quality across the board, in all processes, including sales, development, and manufacturing, in order to reach the targets. In each area of business, key action points for enhancing quality are established every six months based on the quality targets, and execution plans are drawn up and implemented to reach the goals. The degree to which the goals of the execution plans have been achieved is reviewed in six-month increments, and revisions are made by based on the plan-do-check-act (PDCA) cycle.

In order to create sustainable products, continuous improvement brought about by the Quality Management System is essential. Nevertheless, even with an excellent Quality Management System in place, it is not possible to maintain and improve the quality of our products and services if individual employees’ work processes are substandard. Based on the belief that “the following process is your (internal) customer”, we strive to encourage each individual to improve their work processes and to instill a constant awareness of the importance of quality.

Quality Track Record

As of January 2025, there have been no accidents related to product safety, such as product flammability or presence of environmentally harmful materials in excess of regulations, this year.

| 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 | 2022 | 2023 | 2024 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Number of serious product accidents | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| Number of serious legal violations | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

We rate the performance of quality improvement efforts based on feedback from customers. The occurrence of quality issues has been on a consistently downward trend since 2017, indicating that our efforts to improve quality are bearing fruit.

| 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 | 2022 | 2023 | 2024 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Quality issues* | 100* | 108 | 69 | 50 | 48 | 45 | 45 | 44 | 59 | 59 |

* Normalized by setting the level in 2015 as 100.

External Certification

ISO/IATF Certification

We endeavor to provide high-quality, reliable products and services that satisfy customer needs by putting the Quality Management System into practice throughout our entire Group, from development to manufacturing and delivery. With our track record of delivering many products and services to a large number of automotive manufacturers, we make use of tools conforming to strict international automotive standards and engage in continuous efforts to boost quality as part of our commitment to meeting the unique requirements of each customer.

We are certified under ISO 9001, an international standard for quality management systems, and our production facilities and support departments are certified under the IATF 16949 standard for the automotive sector.

| ISO 9001 | 49 facilities certified |

|---|---|

| IATF 16949 | 15 facilities certified |