Anomaly Detection, Condition Monitoring, and Predictive Maintenance – What are they and why you should use them?

Let me begin with the overall picture of electric motors first. We all know that electric motors are an essential component of many industrial and commercial systems. From large manufacturing plants, transportation, and healthcare to household appliances, they play a critical role in various industries. As we can imagine, these applications rely heavily on the smooth and efficient operation of electric motors, which are essential components in these systems. The demand for efficiency and productivity continues to grow and the importance of maintaining these motors has become increasingly crucial. However, electric motors can experience various issues that can impact their performance, efficiency, and longevity. This is where anomaly detection, condition monitoring, and predictive maintenance come into play as three critical practices that help ensure the safe and efficient operation of electric motor-driven applications.

What are these critical practices and techniques and how can we distinguish between them?

First, let’s define our terminology:

Anomaly Detection – is the process of identifying deviations from expected behavior or patterns. In the context of electric motor-driven applications, anomalies can manifest as a sudden change in operating conditions, such as abnormal vibrations, temperature spikes, or power consumption. These changes can indicate the presence of underlying problems, such as worn-out bearings or faulty wiring, which, if not addressed, can lead to more severe damage or even motor failure.

Condition Monitoring – is an ongoing process of collecting and analyzing data on the health and performance of electric motors. By regularly monitoring key performance indicators such as temperature, vibration, and power consumption, ML (machine learning) models can detect subtle changes in motor behavior that may indicate the presence of developing problems. With this information, maintenance technicians can take preventative measures, such as lubrication, cleaning, or repairs, before the issue escalates into a significant problem.

Predictive Maintenance – takes condition monitoring one step further by using advanced analytics and machine learning algorithms to predict when maintenance will be needed.

By analyzing historical data on motor performance and comparing it to real-time sensor readings, predictive maintenance systems can detect anomalies and predict when critical components such as bearings or shafts are likely to fail. With this information, maintenance teams can schedule repairs or replacements proactively, minimizing downtime and maximizing the lifespan of the motor.

So, what’s needed to enable one of these techniques?

The answer to this question requires first, the understanding and identification of the system states to be monitored. Second, we need to identify the best information to be used to detect these states. Third, data and data analysis. By analyzing the data, we can classify data patterns, value combinations, or conditions, enabling the indication between normal and atypical modes of behavior and the definition of the anomaly case with a dedicated best fit machine learning model.

The following ingredients are needed:

- Sensors – Appropriate sensors must be installed in the motor system to collect data on various parameters such as vibration, temperature, current, pressure, magnetic fields, and others, depending on the specific application.

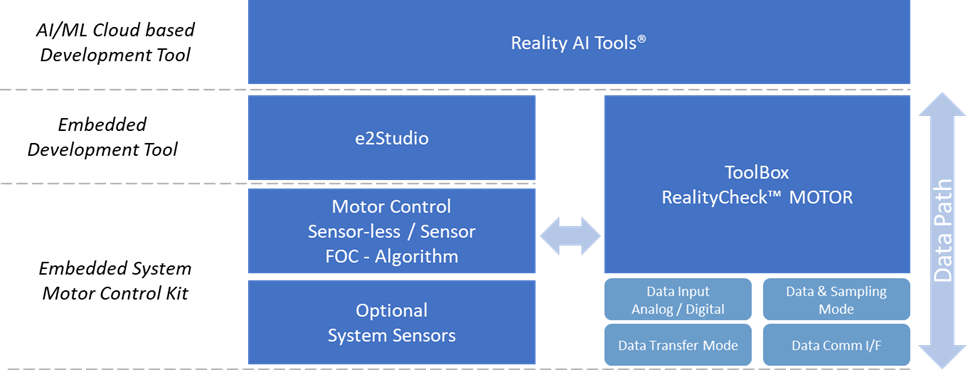

- Data acquisition system – Data from the sensors must be acquired and stored in a database or cloud platform. A data acquisition system is typically used to collect, process, and store the sensor data you’ll need to analyze and use for the development and training of a machine learning model. The RealityCheck™ Motor toolbox was developed specially for this purpose. Figure 1 depicts the typical block diagram involving RealityCheck Motor within the process and data path flow.

- Data processing, analysis, and ML model development – Now we need to analyze the sensor data and identify anomalies or patterns that may indicate potential issues. Based on the data analysis outcome, Reality AI Tools® automatically do this using a variety of methods for feature discovery and model selection.

To understand our machine learning tools more fully and how they can be applied to your data, please visit the Reality AI software page for additional details and use case examples.

But I need to reduce BoM and save costs. How about a sensor-less approach?

The answer is simply yes. A sensor-less approach can provide additional benefits in this context, particularly for applications that may not have sensors built-in for monitoring performance parameters. Sensor-less approaches use ML models to estimate motor performance based on other available data, such as current draw or voltage which are already used in the motor control algorithm. For more information on how and why to use Reality AI Tools with the RealityCheck Motor toolbox, watch the Sensorless Predictive Maintenance for Electric Motor Systems video.

OK, so what’s the deal with RealityCheck Motor?

RealityCheck Motor is an add-on software toolbox that enables anomaly detection, conditional monitoring, and predictive maintenance functionality without requiring the implementation of additional sensors. This means that the electrical signals and parameters already available in the motor can be used from the motor control process as a proxy for other sensors. Using readily available information, RealityCheck Motor enables the collection of minute changes in system parameters that are indicative of anomalies and maintenance issues. It is designed to work seamlessly with Renesas MCUs, MPUs, and motor driven applications, enabling hardware optimization and the creation of machine learning models. This software toolbox along with Reality AI Tools software, provides a low-code automated machine learning platform for creating, validating, and deploying sensor classification or prediction models at scale in the targeted Renesas embedded devices of your choice.

In a nutshell, RealityCheck Motor is the perfect toolbox and add-on functionality for anyone looking to optimize their motor systems by implementing machine learning capabilities to ensure maximum efficiency and uptime.

In conclusion, electric motors are a crucial part of many industrial and commercial applications and their efficient operation is essential to maintaining productivity and reducing costs. By implementing anomaly detection, condition monitoring, and predictive maintenance strategies, businesses can ensure that their motors remain in optimal condition, reducing the risk of downtime and costly repairs and extending the lifespan of their equipment. Visit the RealityCheck Motor page to see how it simplifies this process within the context of your motor control algorithm development.

For more information on real-time analytics and non-visual sensing for anomaly detection and the full suite of Reality AI software solutions from Renesas, check out renesas.com/realityai.