The Covid-19 pandemic, the proliferation of 5G networks and a shortage of skilled manufacturing workers. What do these have in common? They are three macroeconomic drivers accelerating growth of the Industrial Internet of Things (IIoT). According to research firm Statista, the installed base of IIoT-connected devices is projected to explode from 16.4 billion this year to nearly 31 billion in 2025 as the world seizes on high-speed wireless technology and plugs into the cloud to automate everything from farming and smart cities to the factory floor of the future.

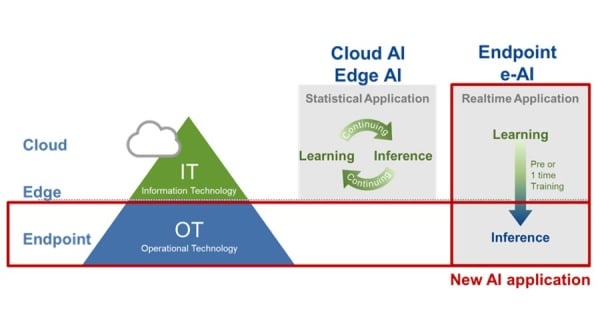

This wave is already breaking in two directions, with manufacturers simultaneously driving their work streams into the datacenter and out to the edge of the IIoT network. The latter trend is particularly interesting as these IIoT endpoint devices aren’t just growing in number, they’re becoming increasingly intelligent. Why is that? In short, low-latency requirements, significant computing and AI capabilities at very low power and cost at the endpoint, privacy and minimal bandwidth needs.

Having stuck their toe in the proverbial water, manufacturers across every industry have come to realize the potential of IIoT to provide predictive maintenance notifications that eliminate surprise equipment failures, incorporate machine learning to improve productivity and defect detection – even enable passport biometric recognition systems to accelerate airport screening and boarding. Some applications are well served by a heavy reliance on the cloud. Weather forecasting, financial services, and actuarial sciences, for instance, are all fields that collect, process, and distribute enormous data sets and where the datacenter is the logical epicenter for transacting massive compute tasks.

There are a host of other applications, however, for which local data capture and execution are necessary. These require near real-time decision-making without porting workloads to and from the cloud. Amazon’s Alexa virtual assistant was an early example of a device with an instantaneous feedback loop. A blood glucose monitor that controls a body-worn insulin pump is another instance where actionable information must be conveyed immediately. These use cases are bounded by latency and the need to actuate locally at the sensor node without data traveling to the network endpoint. This is especially true as IoT moves increasingly to processing in the areas of voice and video.

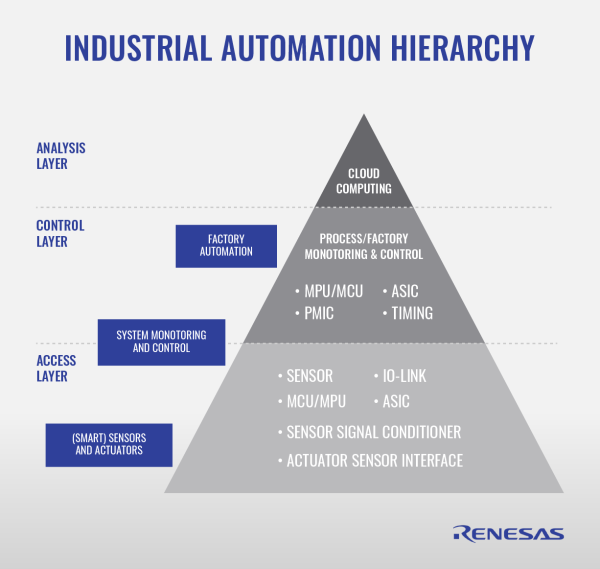

There is a lot of innovation happening in the Industrial IoT area, especially at the foundational access layer, which includes smart sensors, actuators, MCUs, MPUs, ASICs, and I/O. The access layer connects the sensor network to the overall control plane, and because it sits closest to the network endpoint it benefits disproportionately from advanced control, monitoring and analysis capabilities.

Early Industrial IoT applications at this layer typically ran on an ASIC or on an MCU that performed simpler tasks. That is evolving as designers incorporate more advanced MCUs, MPUs and Neural Processing Units (NPUs) capable of running artificial intelligence algorithms and complex compute functions. Even so, these single-core processors were only able to perform jobs sequentially, first sensing the data, and then processing it before sending an instruction to the actuator. The future of IIoT will evolve into multi-core CPUs, multi-threaded neural processing units, and even low-power, cost-efficient FPGAs driving parallel operations to multiple sensors and actuators. This is the intelligence that’s moving toward the IIoT endpoint. This is what will enable automated systems to locally handle most AI-centric workloads below 10 Tera Operations Per Second (TOPS).

With endpoint data creation growth expected to increase at a CAGR of 85 percent from 2017 through 2025, we expect the trend of driving intelligence from the cloud to the Industrial IoT edge will become increasingly common among customers as hardware and software continue to mature. In the end, however, moving intelligence from the cloud to the IIoT endpoint is only possible if we do so power efficiently and sustainably with a goal to extend battery life and improve product reliability. This is part of the Renesas "transformation by design" I referenced in my last blog and is an important differentiator as we seek to help the customers with addressing their market needs.

Please also see the interesting blog by Kaushal Vora: Endpoint Intelligence.

Find information on products and technologies to help you implement AI solutions at renesas.com/AI.