5V, Rail-Rail I/O, Zero-Drift, Programmable Gain In Amp Evaluation Board

The ISL2853xEV2Z and ISL2863xEV2Z boards allow simple evaluation of the ISL2853x and ISL2863x 5V zero-drift programmable gain instrumentation amplifiers. The boards are...

The ISL28533 5V zero-drift rail-to-rail input/output (RRIO) Programmable Gain Instrumentation Amplifiers (PGIA). This instrumentation amplifier features low offset, low noise, low gain error, and high CMRR. It is ideal for high precision applications over the wide industrial temperature range. This in-amp is designed with a unique 2-bit, 3-state logic interface that allows up to 9 selectable gain settings. The ISL2853x single-ended output amplifier includes an additional uncommitted zero-drift amplifier, useful to buffer the REF input or used as a precision amplifier.

The ISL2853xEV2Z and ISL2863xEV2Z boards allow simple evaluation of the ISL2853x and ISL2863x 5V zero-drift programmable gain instrumentation amplifiers. The boards are...

The ISL2853xEV2Z and ISL2863xEV2Z boards allow simple evaluation of the ISL2853x and ISL2863x 5V zero-drift programmable gain instrumentation amplifiers. The boards are...

The ISL2853xEV2Z and ISL2863xEV2Z boards allow simple evaluation of the ISL2853x and ISL2863x 5V zero-drift programmable gain instrumentation amplifiers. The boards are...

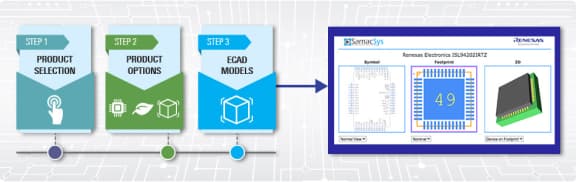

Schematic symbols, PCB footprints, and 3D CAD models from SamacSys can be found by clicking on products in the Product Options table. If a symbol or model isn't available, it can be requested directly from the website.

Applied Filters:

This video examines the use of instrumentation amplifiers (INA or in amps) for sensor applications. Intersil discusses the basics of the three-op amp INA, advantages of the zero-drift amplifiers, why use an RF input filter, monitoring sensor health, the advantages of programmable gain amplifiers and concludes with application examples for a sensor health monitor and an active shield guard drive.

Hello, my name is Don LaFontaine. I'm an application manager in the precision analog products group at Intersil. This video examines the use of instrumentation amplifiers (INA or in-amp) for sensor applications. Many industrial and medical applications use instrumentation amplifiers to condition small signals in the presence of large common mode voltages in DC potentials. This video will discuss the basics of the three-op amp in-amp, advantages of the zero-drift amplifiers, why would you use an RF input filter, monitoring of sensor health, and the advantages of programmable amplifier.

Let's first discuss the basics of the three-op amp in-amp. The high-impedance inputs of the instrumentation amplifier, coupled with the high common mode rejection, is the key to many sensor applications. The high-input impedance is achieved by using the non-inverting inputs of the input stage, without having to resort to any feedback tricks. The three-op amp circuit strips off the common mode voltage and amplifies the sensor signal with very little error. Consideration of the input common mode voltage, VCM, and the differential voltage, VD, must be taken into account to avoid saturating the input amplifiers. The saturating input stage could appear normal to the following processing circuitry and have disastrous consequences. Maximum design margin to avoid saturating the input stage can be achieved by using amplifiers with rail to rail input and output configurations.

The following discussion gives the basic operation of the three-op amp in-amp that illustrates how the amplifier handles both common mode and differential signals. Common mode signals, VCM, is defined as the voltage common to both inputs and is the average of the sum of INA plus and INA minus. The differential voltage, VD, is defined as the net difference of INA plus and INA minus. The node voltages on the inputs of the INA, as a result of applying a common mode voltage and differential voltage, are shown. In the non-saturated mode, the op amp action of A one and two applies the differential voltage across the gain setting resistor, RG, which generates a current, ID. This results in the voltage equations as shown at VA plus and VA minus. Notice these equations. Only the differential component, VD, is amplified by the gain. While the common mode voltage, VCM, passes the input stage with unity gain and is subsequently canceled out by the common mode rejection, the amplifier A3. This action enables the in-amp to easily and effectively remove common mode signals from the desired differential signal, which is exactly what the doctor ordered. Because often times the differential signal from various sensors needs to be amplified by a hundred to a thousand times to get the sensitivity required for the measurement.

The input offset voltage of all amplifiers, regardless of process technology or the architecture, will vary over temperature and time. Traditional amplifiers will spec this limit on the order of several microvolts to tens of microvolts per degree C. This offset drift can be problematic in high-precision applications. It cannot be calibrated out during initial manufacturing. In addition to drift over temperature, an amplifier's input voltage can drift over time. Zero-drift amplifiers inherently minimize both the drift over temperature and time, by continually self-correcting the offset voltage. Some zero-drift amplifiers correct the offset as much as ten thousand times a second. Zero-drift amplifiers like the ISL2853x and the ISL2863x can deliver very low offset voltage drift of 5nV/°C. Zero-drift amplifiers also eliminate 1/f noise, or flicker noise. 1/f noise is a low-frequency phenomenon caused by irregularities in the conduction path and noise due to currents within the transistors. This makes zero-drift amplifiers ideal for low-frequency input signals near DC, such as output from strain gauges, pressure sensors, thermal couples, to name a few.

The proliferation of wireless transceivers and in portable applications has led to an increased attention to an electronic circuit's ability to operate in the vicinity of high-frequency radio transmitters such as Bluetooth. RF suppression is needed to ensure interference-free operation of the sensor. In EMI-sensitive applications, the high-frequency RF signal can appear as a rectified DC offset at the output of the precision amplifier. Because the gain of the precision front end can be 100 or greater, it's critical not to amplify any conducted or radiated noise that may be present in the amplifier's inputs. An easy solution to this problem is to include RF filters on the input of the in-amp. The ISL2853x and the ISL2863x family of in-amps have RF filters on the inputs.

The ability to monitor any change to the sensor over time can help with robustness and accuracy of the measurement system. Direct measurements across the sensor will more than likely corrupt the readings. A solution is to use the input amplifiers of the in-amp as the impedance buffer. The ISL2853x and 2863x instrumentation amplifiers give the user access to the outputs of the input amplifiers, for just this purpose. By tying two resistors, VA plus and VA minus, the buffer input common mode voltage is extracted at the midpoints of the resistors. This voltage can be sent to an ADC sensor monitoring or feedback control, improving the precision and accuracy of the sensor over time.

It is widely accepted that you cannot build a precision differential amplifier using discrete parts and get good CMRR, performance, or gain accuracy. This is due to the matching of the four external resistors used to configure the op amp in a differential amplifier. Integrated solutions have improved the matching of resistors on chip but still have the absolute matching problem to external resistors when used to set the gain of an amplifier. The tolerance between on-chip resistors values and external resistor values can typically be 20% and as high as 30%. Another source of error is the thermal performance between internal and external resistors. It is possible to have opposite temperature coefficients between the internal and the external resistors.

A programmable gain amplifier solves this problem by having all resistors on board. The gain resistors for this type of amplifier can be less than 1%, with trim capabilities on the order of 0.5% typical and plus and minus 0.4% max across temperature.

Intersil's ISL2853x and ISL2863x family of programmable in-amps offer both single-ended and differential-ended outputs with three different gain sets. Each gain set has nine different gain settings as shown. The gain sets were determined for specific applications in mind and are shown at the bottom of each column.