Understanding the principle and application of high efficiency motors: 1 of 3

A motor converts supplied electrical energy into mechanical energy. Various types of motors are in common use. Among these, brushless DC motors (BLDC) feature high efficiency and excellent controllability, and are widely used in many applications. The BLDC motor has power-saving advantages relative to other motor types.

Motors are Power Delivery Machines

When engineers are faced with the challenge of designing electrical equipment to perform mechanical tasks, they might think about how electrical signals get converted to energy. So actuators and motors are among the devices that convert electrical signals into motion. Motors exchange electrical energy to mechanical energy.

The simplest type of motor is the brushed DC motor. In this type of motor, electrical current is passed through coils that are arranged within a fixed magnetic field. The current generates magnetic fields in the coils; this causes the coil assembly to rotate, as each coil is pushed away from the like pole and pulled toward the unlike pole of the fixed field. To maintain rotation, it is necessary to continually reverse the current—so that coil polarities will continually flip, causing the coils to continue “chasing” the unlike fixed poles. Power to the coils is supplied through fixed conductive brushes that make contact with a rotating commutator; it is the rotation of the commutator that causes the reversal of the current through the coils. The commutator and brushes are the key components distinguishing the brushed DC motor from other motor types. Figure 1 illustrates the general principle of the brushed motor.

Figure 1: Operation of the Brushed DC Motor.

Fixed brushes supply electric energy to the rotating commutator. As the commutator rotates, it continually flips the direction of the current into the coils, reversing the coil polarities so that the coils maintain rightward rotation. The commutator rotates because it is attached to the rotor on which the coils are mounted.

Common Motor Types

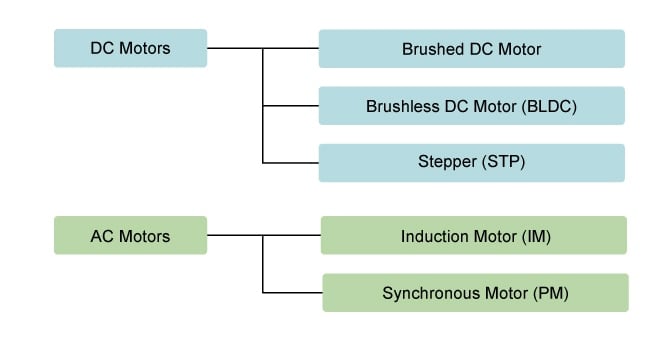

Motors differ according to their power type (AC or DC) and their method for generating rotation (Figure 2). Below, we look briefly at the features and uses of each type.

Figure 2: Different Types of Motors

Brushed DC motors, featuring simple design and easy control, are widely used to open and close disk trays. In cars, they are often used for retracting, extending, and positioning electrically-powered side windows. The low cost of these motors makes them suitable for many uses. One drawback, however, is that brushes and commutators tend to wear relatively quickly as a result of their continued contact, requiring frequent replacement and periodic maintenance.

A stepper motor is driven by pulses; it rotates through a specific angle (step) with each pulse. Because the rotation is precisely controlled by the number of pulses received, these motors are widely used to implement positional adjustments. They are often used, for example, to control paper feed in fax machines and printers—since these devices feed paper in fixed steps, which are easily correlated with pulse count. Pausing can also be easily controlled, as motor rotation stops instantly when the pulse signal is interrupted.

With synchronous motors, rotation is synchronous with the frequency of the supply current. These motors are often used to drive the rotating trays in microwave ovens; reduction gears in the motor unit can be used to obtain the appropriate rotational speeds to heat food. With induction motors, too, the rotation speed varies with frequency; but the movement is not synchronous. In the past, these motors were often used in electric fans and washing machines.

There are various types of motor in common use. In this session, we look at the advantages and applications of brushless DC motors.

Why Do BLDC Motors Turn?

As their name implies, brushless DC motors do not use brushes. With brushed motors, the brushes deliver current through the commutator into the coils on the rotor. So how does a brushless motor pass current to the rotor coils? It doesn’t—because the coils are not located on the rotor. Instead, the rotor is a permanent magnet; the coils do not rotate, but are instead fixed in place on the stator. Because the coils do not move, there is no need for brushes and a commutator. (See Figure. 3.)

With the brushed motor, rotation is achieved by controlling the magnetic fields generated by the coils on the rotor, while the magnetic field generated by the stationary magnets remains fixed. To change the rotation speed, you change the voltage for the coils. With a BLDC motor, it is the permanent magnet that rotates; rotation is achieved by changing the direction of the magnetic fields generated by the surrounding stationary coils. To control the rotation, you adjust the magnitude and direction of the current into these coils.

Figure 3: A BLDC Motor.

Since the rotor is a permanent magnet, it needs no current, eliminating the need for brushes and commutator. Current to the fixed coils is controlled from the outside.

Advantages of BLDC Motors

A BLDC motor with three coils on the stator will have six electrical wires (two to each coil) extending from these coils. In most implementations three of these wires will be connected internally, with the three remaining wires extending from the motor body (in contrast to the two wires extending from the brushed motor described earlier). Wiring in the BLDC motor case is more complicated than simply connecting the power cell’s positive and negative terminals; we will look more closely at how these motors work in the second session of this series. Below, we conclude by looking at the advantages of by BLDC motors.

One big advantage is efficiency, as these motors can control continuously at maximum rotational force (torque). Brushed motors, in contrast, reach maximum torque at only certain points in the rotation. For a brushed motor to deliver the same torque as a brushless model, it would need to use larger magnets. This is why even small BLDC motors can deliver considerable power.

The second big advantage—related to the first—is controllability. BLDC motors can be controlled, using feedback mechanisms, to delivery precisely the desired torque and rotation speed. Precision control in turn reduces energy consumption and heat generation, and—in cases where motors are battery powered—lengthens the battery life.

BLDC motors also offer high durability and low electric noise generation, thanks to the lack of brushes. With brushed motors, the brushes and commutator wear down as a result of continuous moving contact, and also produce sparks where contact is made. Electrical noise, in particular, is the result of the strong sparks that tend to occur at the areas where the brushes pass over the gaps in the commutator. This is why BLDC motors are often considered preferable in applications where it is important to avoid electrical noise.

Ideal Applications for BLDC Motors

We’ve seen that BLDC motors offer high efficiency and controllability, and that they have a long operating life. So what are they good for? Because of their efficiency and longevity, they are widely used in devices that run continuously. They have long been used in washing machines, air conditioners, and other consumer electronics; and more recently, they are appearing in fans, where their high efficiency has contributed to a significant reduction in power consumption.

They are also being used to drive vacuum machines. In one case, a change in the control program resulted in a large jump in rotational speed—an example of the superlative controllability offered by these motors.

BLDC motors are also being used to spin hard disc drives, where their durability keeps the drives operating dependably over the long term, while their power efficiency contributes to energy reduction in an area where this is becoming increasingly important.

Toward Wider Usage in the Future

We can expect to see BLDC motors used in a wider range of applications in the future. For example, they will probably be widely used to drive service robots—small robots that deliver services in fields other than manufacturing. One might think that stepper motors would be more suitable in this type of application, where pulses could be used to precisely control positioning. But BLDC motors are better suited to controlling the force. And with a stepper motor, holding the position of a structure such as a robot arm would require a relatively large and continuous current. With a BLDC motor, all that would be required is a current proportionate to the external force—allowing for more power-efficient control. BLDC motors may also be replacing simple brushed dc motors in golf carts and mobility carts. In addition to their better efficiency, BLDC motors can also deliver more precise control—which in turn can further extend battery life.

BLDC motors are also ideal for drones. Their ability to deliver precision control makes them especially suited for multirotor drones, where the drone’s attitude is controlled by precisely controlling the rotational speed of each rotor.

In this session, we have seen how BLDC motors offer excellent efficiency, controllability, and longevity. But careful and proper control is essential to taking full advantage of these motors’ potential. In our next session, we will look at how these motors work.

Module List

- What are Brushless DC Motors

- Controlling BLDC Motors

- Renesas Solutions for BLDC Motor Control