While the term software-defined vehicle, or SDV, has been used often over the past few years, software has been improving the automobile experience – and safety – for close to half a century now. Since the introduction of software-managed electronic controls in the 1970s, the automotive fatality rate has dropped by 70 percent for every 100 million miles driven, from 4.5 in 1970 to less than 1.33 in 2021. Similarly, software-driven precision controls and engine operation optimization have reduced fossil fuel emissions by 70 percent since the 1970s.

What's been missing until this point, however, is a truly software-first SDV approach that supports hardware and software development in parallel by combining cloud-native development with a customizable simulation environment.

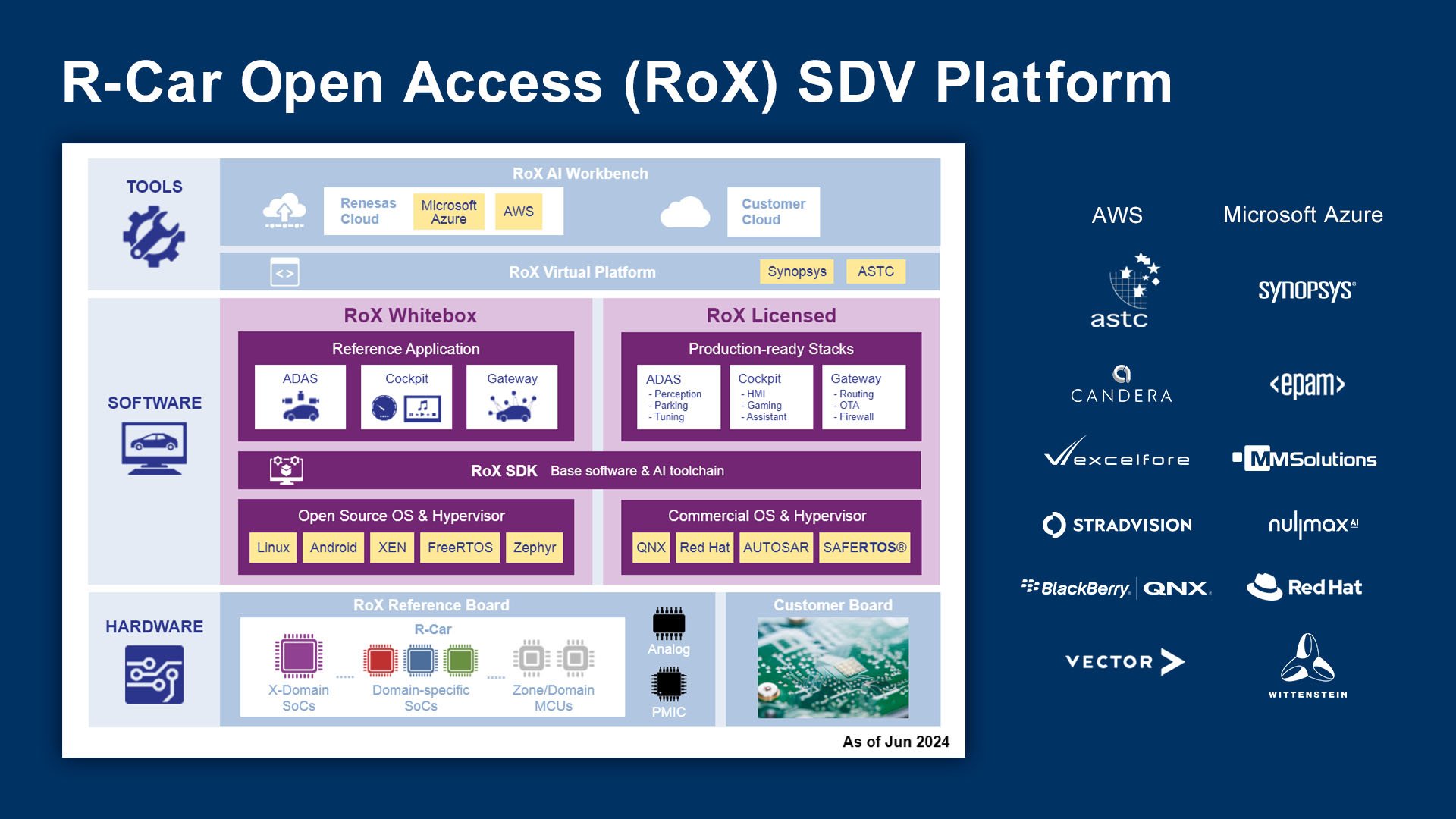

Enter the newly released Renesas R-Car Open Access (RoX) platform. Designed for the R-Car Family, RoX simplifies the integration of hardware and software and speeds up development for automotive engineers. The R-Car Family is the only hardware architecture that accommodates the full range of processing requirements – from zonal ECUs to high-end central compute – in order to rapidly develop next-generation SDVs with secure, continuous software updates in everything from entry-level to luxury-class models.

Why SDV?

SDV platforms mark the next frontier in automotive technology, transforming traditional vehicles into systems that are adaptive, personalized, and interconnected. Unlike conventional vehicles, where functionality is primarily hardware-driven and changes require physical modifications, SDVs leverage software to control, manage, and update vehicle operations. This paradigm shift offers unprecedented flexibility, scalability, and efficiency in vehicle design, maintenance, and the overall driving experience.

At the core of an SDV is its ability to decouple hardware from software, allowing for over-the-air (OTA) updates that are conceptually similar to those used in computers and IoT devices but with an additional complex layer of safety, security, and robustness. This means that vehicle manufacturers can push updates to fix bugs, enhance features, and even introduce new functions without requiring a visit to the dealership. For consumers, this translates to a more responsive and continually improving vehicle ownership experience.

One of the most significant advantages of SDVs is enhanced safety for autonomous driving. Software updates can continuously improve the vehicle's ability to detect and respond to its environment by integrating advancements in artificial intelligence (AI) and machine learning (ML). This adaptability is crucial as the automotive industry progresses toward fully autonomous vehicles, which require constant refinement and real-time information processing.

Moreover, SDVs promote better vehicle management and diagnostics. Advanced telemetry can provide real-time data on vehicle performance and predict maintenance needs before they become critical issues. This can reduce downtime and extend the vehicle's lifespan, providing cost savings and reliability to fleet operators and individual owners alike.

The SDV model also facilitates seamless integration with other digital ecosystems. Vehicles can communicate with smart city infrastructure, other vehicles, and personal smart devices, creating a holistic network that enhances convenience and efficiency in urban mobility.

SDVs Need to Deliver a Successful Digital Transformation

A typical modern car now has more than 100 million lines of code delivered by a diverse supplier base, which makes software testing and ECU integration extremely complicated. Increasing the complexity is the fact that most development processes are "agile" with requirements that need to be validated with nightly continuous integration/continuous development regressions. The diversity of the software supplier base further increases the likelihood of bugs due to integration complexity.

Building an SDV presents new challenges spanning technical, regulatory, and operational domains. The following captures the diversity and interconnectedness of these challenges:

- Complex Software Integration: Ensures seamless interoperability between sophisticated operating systems while maintaining high performance and reliability

- Cybersecurity Risks: Robust cybersecurity protects against hacking, data breaches, and other malicious activities, including securing communication channels

- Regulatory Compliance: Guarantees adherence to differing regional standards and regulations concerning vehicle safety, data privacy, and emissions

- Software Updates: Manages OTA software updates to ensure they are delivered reliably and securely to a global fleet of vehicles

- Reliability and Redundancy: Redundant systems ensure continuous operation in the event of a software or hardware failure

- Data Privacy and Ethics: Provides stringent data protection measures and transparent data usage while addressing autonomous driving ethical considerations

- High Development Costs: Manages costs associated with developing, testing, and deploying advanced software and hardware, particularly for smaller manufacturers

Assessing the Modern Automotive Value Chain in a Digital Age

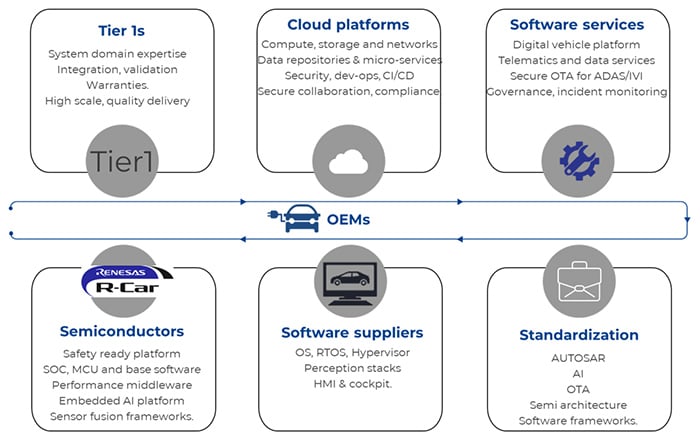

Until recently, cars were conceptualized, designed, and delivered by OEMs. Tier 1s helped fill in the gaps for component integration, testing, validation, and maintenance services. Tier 2 and Tier 3 suppliers delivered software and hardware components to the Tier 1s to drive the integration tasks.

The modern automotive value chain and the underlying electrical/electronic (E/E) architectures have been upended due to the major driving forces of electrification, autonomy, and the connected nature of the fleet. Digitalization has taken center stage. While some of the responsibilities of traditional Tier 1 players are being absorbed by OEMs, a wave of entirely new service providers has appeared in the value chain, including cloud platform and software services companies that aggregate and integrate the various pieces – both during development and in the field.

This new constantly upgradable car can only be delivered through a completely upgradable end-to-end software stack that is secure and easy to develop, test, and maintain. Many traditional suppliers, including semiconductor, operating system, and middleware companies, which originally supplied an isolated component to the Tier 1s, are now required to build a product stack to support the needs of an entire OEM fleet that is defined by an SDV feature set.

Renesas' RoX Supports and Accelerates SDV Development

Renesas' RoX SDV platform is designed for current generation R-Car SoCs, the upcoming R-Car Gen 5 MCU/SoC Family, and future devices. The new platform provides OEMs and Tier 1 suppliers the flexibility to design a broad range of scalable compute solutions for ADAS, IVI, gateway, and cross-domain fusion systems as well as body control, domain, and zone control.

Thanks to a new unified hardware architecture based on Arm® CPU cores, customers developing with the R-Car Gen 5 devices can reuse the same software and tools across diverse E/E applications that span car models and generations, preserving their engineering investments.

Today, OEMs and Tier 1 suppliers are heavily investing in software development and maintenance. Renesas understands this challenge and is closely working with our customers and partners to deliver a flexible, ready-to-deploy development solution that can be maintained throughout the vehicle's lifespan.

News & Additional Resources

| Title | Type | Date |

|---|---|---|

| Renesas Unveils Processor Roadmap for Next-Gen Automotive SoCs and MCUs | News | Nov 7, 2023 |