Motors are indispensable for the development and maintenance of our society and are said to account for 40% of the world's electricity consumption, making them an essential part of our lives. Equipment with motors must be compact, high-performing, and safe, and energy-efficient motor control is required to achieve sustainable development goals and carbon neutrality.

Renesas has long been a leader in embedded processing technology for the motor control market. With more than a decade of shipping billions of motor control-specific processors to thousands of customers worldwide, we offer the industry’s broadest product lineup and most comprehensive technology portfolio plus an unmatched ability to deliver complete solutions encompassing an array of critical functions.

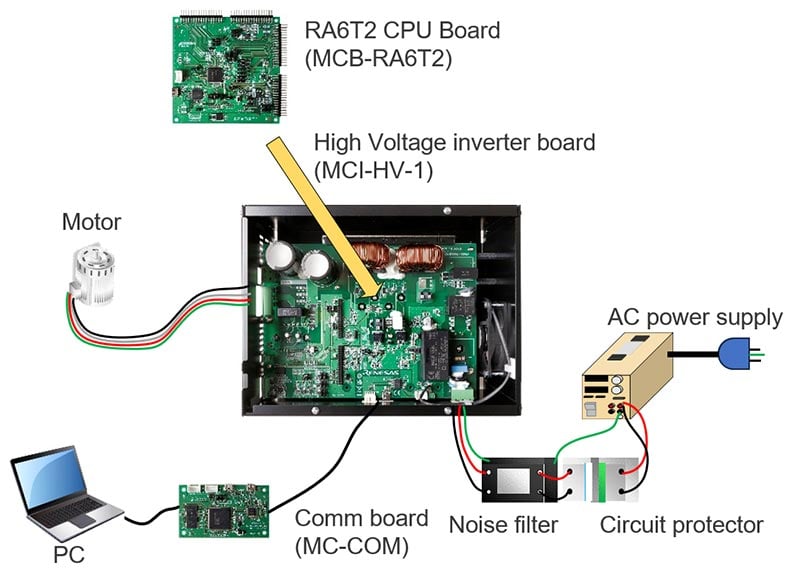

We continue leveraging this heritage to help customers solve problems they encounter across a range of industrial, consumer, and building automation markets. For those requiring higher voltage operation, we have released a high-voltage motor control solution for BLDC/induction motors. This solution consists of an inverter board and sample code to enable easy evaluation and simplify system development. The complete design package includes the application note, sample code, and PC GUI environment to support customer development and help improve user experience.

This solution supports RA6T2 MCUs and we will expand to other RA motor control devices in the near future.

Inverter Board Overview

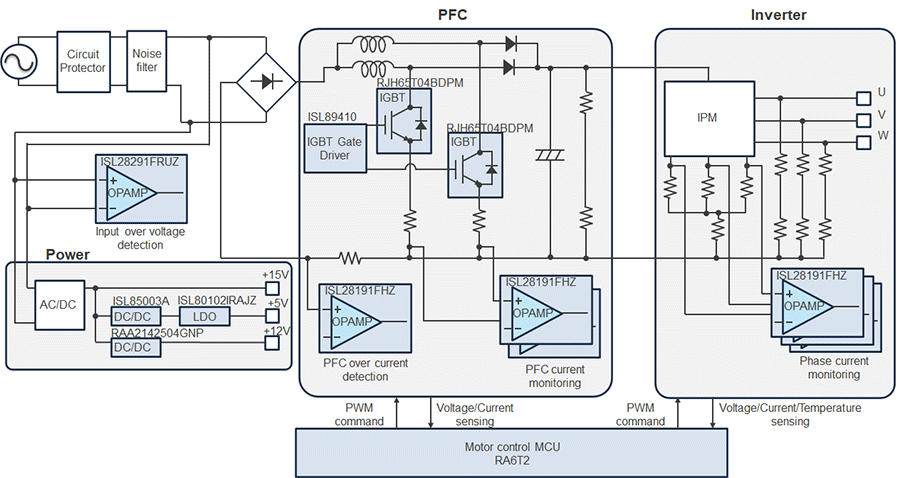

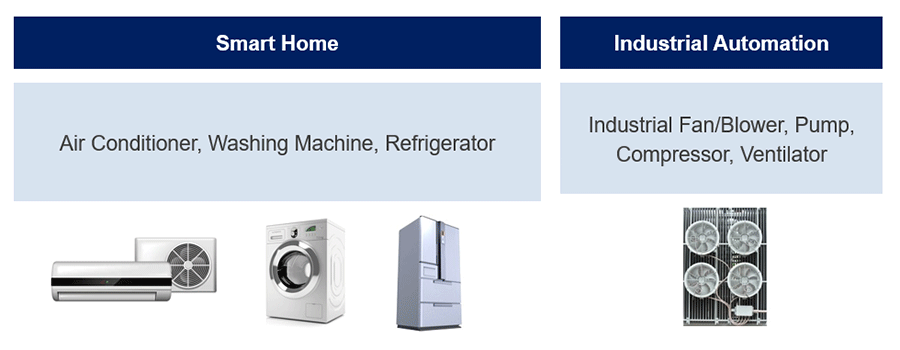

The inverter board allows users to evaluate motor control using a high-voltage (100V/200V) BLDC/induction motor at ease and is equipped with a power factor correction (PFC) function. Maximum inverter output is 2kW and PFC output is 1kW which is ideal for home appliances such as air conditioners, refrigerators, and washing machines among others. The board also supports a fast discharge function when the power is shut off, enabling a connection switch in a short time and efficient development.

Key Features

- 240V AC and 390V DC input voltage, 2kW max output (when DC input)

- Built-in PFC: Max output 1kW with single/interleave control

- Supports 1-/3-shunt current detection

- Built-in protection functions such as overcurrent detection, short circuit prevention, overheat detection, overvoltage prevention, and inrush current prevention

- Enables control/debug with PC safety due to the built-in reinforced insulation comm I/F

The inverter board also supports dual motor control using two of these boards and a CPU board supporting dual motor control and built-in reinforced insulation sensor I/F support hall sensor encoder input. We will release sample code that supports these configurations in the near future.

Sample Code and Application Note

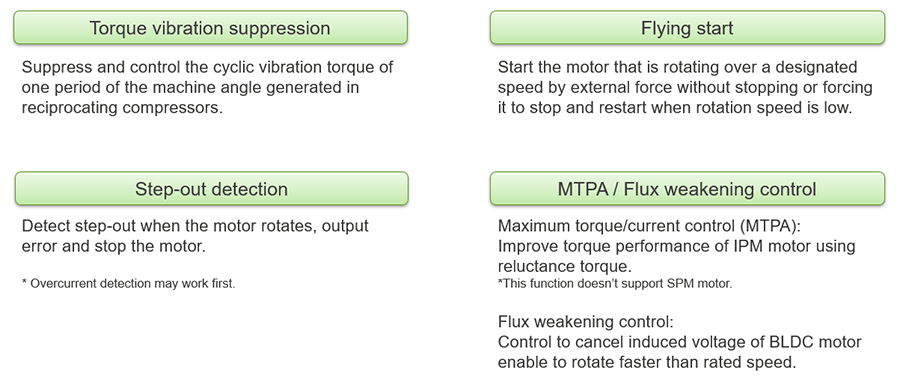

Sample code supports digital PFC power supply control. The PFC control setting can be changed or adjusted according to required power specs and applications. Also, this code implements various BLDC motor control functions that focus mainly on home appliances.

- Sample code implementing high-voltage motor control (PFC control, etc.) and control method (vector control, etc.)

- Additional special functions for high-voltage motor control such as torque vibration suppression, flying start, step-out detection, MTPA/Flux weakening control

- App note describes the control method explanation and how to implement on an MCU

As you can see from the overview of the inverter board and sample code, this high-voltage motor control solution is ideal for systems using high-voltage motors including home appliances, as well as industrial fans or blowers, pumps, and compressors.

The high-voltage motor control solution supports the Renesas Motor Workbench, a development support tool for debugging, analyzing, and tuning motor control programs, including motor parameters estimation.

To learn more or to get a board, please visit the MCI-HV-1 motor control inverter board page.