Looking for a more accurate position sensor!!

Manufacture the optimum position sensor in-house!!

Reduce the cost of the position sensor!!

I am writing this article for those who have the above requests.

Hello everyone. My name is Chen Guan Yuan from Renesas Japan. I am responsible for the position sensor IPS2550 for xEV applications and I provide technical support for customers.

Renesas offers an inverter solution using the inductive position sensor IPS2550 for xEV applications.

In recent years, due to carbon-neutral strategies in each country, gasoline-powered vehicles are gradually being replaced by electric vehicles. At the COP26 conference held in the United Kingdom in November 2021, more than 20 member countries agreed to cease production of gasoline vehicles in 2040. Therefore, no one can stop the arrival of the era of new energy vehicles. Today’s OEMs are electrifying their fleets and newcomers are entering the market developing and manufacturing electric vehicles.

Today, I would like to introduce a product that all xEV developers should switch to. It is an in-vehicle position sensor "Inductive position sensor IPS2550" that is indispensable for electric vehicles. The reason developers should switch from a resolver to this solution is because it is more accurate, less expensive and easy to use.

First, I would like to introduce this product, inductive position sensor IPS2550.

Based on Renesas' position detection technology, the IPS2550 detects the position of the target metal based on the principle of electromagnetic induction of the coil.

Looking for a more accurate position sensor!!

Although the IPS2550 is designed based on the motor axis, angular accuracy can be optimized by matching the number of sectors in the sensor with the number of pole pairs in the motor. The motor can rotate with an electrical angle up to 600,000 rpm, and can achieve higher accuracy than other position sensors. It is about 2 to 3 times more accurate than a conventional resolver.

- High accuracy ≤ 0.1% full scale (ideal coil)

- Supports up to 600,000 (el) rpm

Manufacture the optimum position sensor in-house!!

Since the IPS2550 detects the position of the target metal based on the principle of electromagnetic induction of the coil, there are no restrictions on the type and shape of the motor, and it is possible to flexibly respond to all placements.

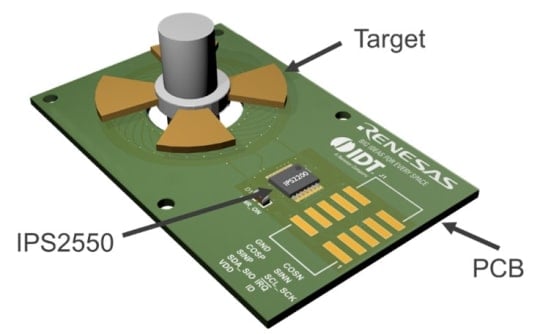

The system is simple consisting of only the configuration of the IPS2550 position sensor, the target, the PCB, and the semiconductor as shown below. Mechanical products such as resolvers require considerable know-how and precision manufacturing equipment. On the other hand, the IPS2550 requires only a board and a target, which eliminates the need for special manufacturing equipment and makes it easy to manufacture a unique IPS2550 position sensor.

For xEV developers, we support coil design from sensor concept to coil data with Renesas expertise. We support the system analysis and feasibility study, coil design, optimization, with the result being the coil Gerber data. We also provide various design examples as CRB (Customer Reference Board Catalog) for xEV developers.

Reduce the cost of the position sensor!!

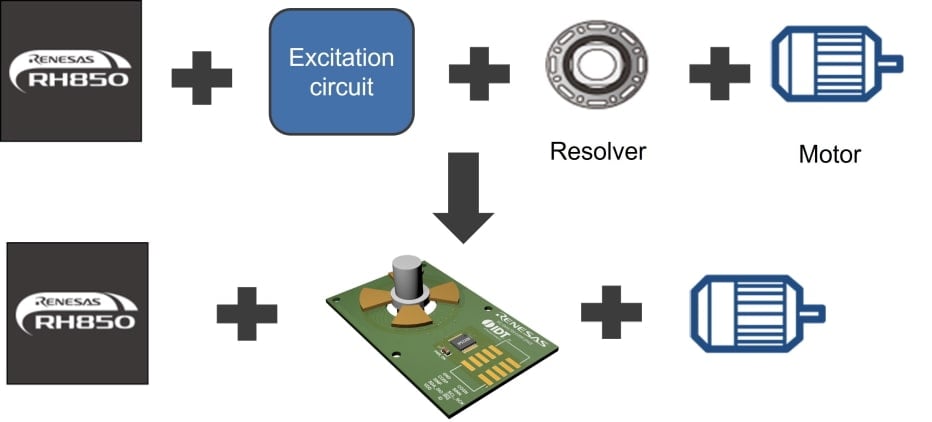

When using a conventional resolver as a position sensor in xEV applications, it is necessary to fix the resolver body to the motor, connect it to the motor shaft, control board, and excitation circuit. When using IPS2550, only the following configuration is available. By reducing the number of BOMs, the BOM cost of the component boards can be reduced by more than 30% compared to resolver solutions.

Next, I would like to introduce the xEV Inverter Solution Using IPS2550.

The position sensor solution realizes high-precision angle detection, at a low cost using in-house production of the position sensor utilizing IPS2550. The inverter with 100kW output capability fits in a 3.9L volume which is ideal for xEV applications. The whole position detection system has been verified to be resistant to the noise present in this high voltage inverter environment.

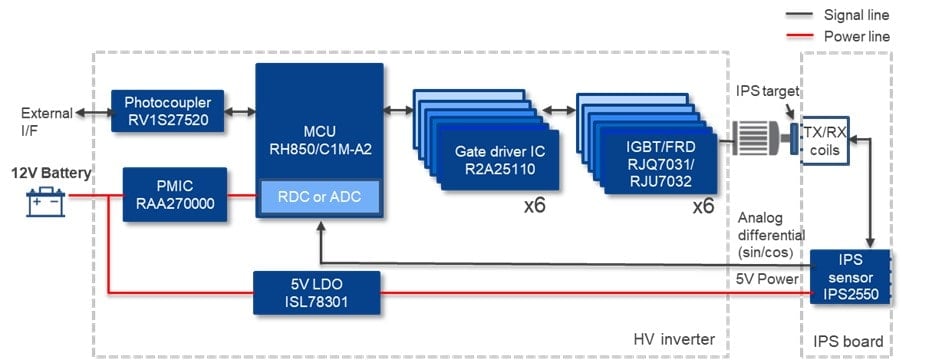

The solution is built upon Renesas products which are optimized for this application including IPS2550, RH850 / C1MA2 microcontroller, PMIC, gate drive IC, IGBT / FRD bare die, and photocoupler. Renesas supports customers with complete support including semiconductor + hardware system design + software system design.

Below is a system block diagram.

Ease of use as a system

We support our customers' early market launch by providing sample software for evaluation, providing the coil design examples mentioned above, and supporting the custom coil design process.

The xEV inverter solution using IPS2550 is ideal for xEV developers

Looking for a more accurate position sensor!!

Manufacture the optimum position sensor in-house!!

Reduce the cost of the position sensor!!

Renesas would love to help xEV developers who have the requests above.

If you are interested in our solutions and support of experts, please contact our sales staff.