Hello everyone. I am Yamagata, in charge of advertising for Renesas Electronics' RX microcontrollers (MCU).

To celebrate the RX 10th anniversary, we interviewed Daikin Industries Co., Ltd (hereafter Daikin) and now share their user experiences in using the RX MCUs. Daikin is a specialist in air conditioning providing air conditioners to more than 150 countries and regions around the world. Daikin has been using the RX microcontroller for the control of many air conditioners, including the famous room air conditioner model - "Ururu Sarara".

The interviewees are Yasuki Taguchi, a cheerful and pleasant personality who is involved in hardware development, and Tomohiro Sato, who is involved in software development and is humorous and modest.

On the day of the interview, we first disinfected both hands at the entrance of the building where Daikin's meeting room, the venue, was located. The conference room was fully equipped with an air purifier and has a round table with 30 seating. The COVID-19 countermeasures were perfect. An outdoor unit and two control boards are also in the conference room. These are the control boards of the first model and the latest model using RX MCU. The distributor Tachibana Eletech (hereinafter referred to as Tachibana) who accompanied us was deeply moved by Daikin's kindness to show the product for this interview! In this warm atmosphere, Mr. Taguchi and Mr. Sato enthusiastically talked about Daikin's commitment to developing an air conditioner.

The Challenge of Sensorless in Inverter Control of Air Conditioners and the Contribution of RX

Which is the first model using the RX MCU?

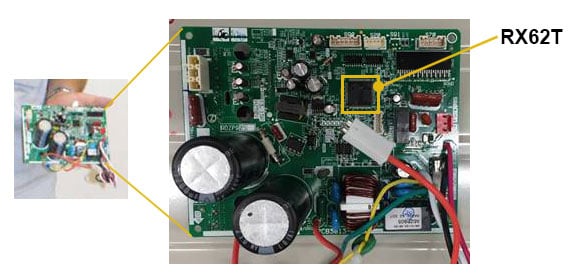

Taguchi: The 2012 model is the first model using RX62T. Since then, RX is used in many newly developed outdoor units. After launching the ‘urusara’ model, they introduced a basic model concept making more compact outdoor units and as a result further reducing the size of the inverter control board. In the industry, many manufacturers reduce costs by using single-sided boards, but we have devoted ourselves to making double-layered glass epoxy boards that are safer against breakdowns and heat; and smaller. With a smaller board, the housing needed is smaller and this helps Daikin to successfully lowered the cost and reduced the energy cost in the life cycle. The palm-sized board is still considered the industry's top class now.

Figure 1. Palm-sized outdoor unit control board based on a basic model concept

Why is RX selected?

Taguchi: RX is selected due to RX’s CPU processing performance and built-in flash memory. Real-time performance was important in order to utilize our ODM (Outdoor Drive Motor) technology and the processing speed of RX62T was necessary.

Sato: When I first saw the RX benchmark, I thought, "Is this processing speed true?" I was surprised at the good performance compared to other microcontrollers. Also, the ability to rewrite flash memory without stopping the operation of the program, BGO, was also attractive as no other company was offering such additional functions.

Taguchi: We took on the challenge of controlling both the fan and compressor of the outdoor unit with a single MCU without using a position sensor in the basic model concept. The MCU needs to be able to control the two inverters and have the processing capacity to perform real-time processing in each control cycle and I thought RX fits the bill. As a result, we were able to reduce the number of parts, such as hall sensors.

Thank you for using RX for about 10 years. What are the memories you have during product development?

Taguchi: The first model using RX MCU is developed in 2011 and the Renesas factory was damaged by the Great East Japan Earthquake, and I was worried about the supply of the MCUs. However, I was able to launch the product without any major impact. Actually, I heard later that it was very difficult to secure the MCU supply, but at that time we were unaware of the difficulties at all and proceeded with the development smoothly. Thank you very much.

Yamagata: I think both Renesas Sales and Tachibana have worked very hard.

Taguchi: During the development of the basic model concept, we got stuck in a problem and co-debugged in Tokyo just before the Golden Week. Tachibana placed the under-development inverter in a suitcase and brought it back from Shiga to Tokyo by riding the super express bullet train (Shinkansen) and taxi. They were even scolded by the taxi driver for placing the suitcase on the seat, as it will dirty the seat. We figured out the cause and took the measures accordingly, and I thought the consecutive holidays will be spent at work.”

Sato: I also recalled troubleshooting issues around the Christmas period in one year. There was a problem that could not be solved, and we took the motor back to analyze it on both sides. We both wondered whether we would spend the New Year Holidays working on this issue.

Yamagata: Both Renesas and Tachibana’s person in charge applied to work during the New Year holidays.

Sato: The issue was resolved just before the end of the year and I was the only one writing the report next to somebody’s year-end party. Although the development issues are tricky, we could resolve the problem with Renesas and Tachibana.

Yamagata: Air conditioners have large voltages and currents, so it is difficult to apply probes on measuring instruments, and analysis requires time and know-how. Hence, there are many memorable challenges after using RX in many models for 10 years.

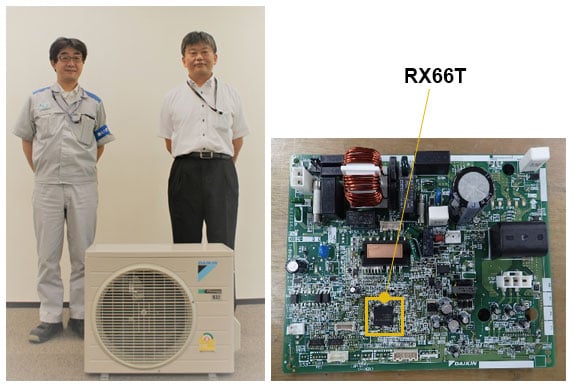

Which is the latest model using RX66T?

Taguchi: The newest model is a volume zone model for Asia. This time, we needed two sensors, a compressor and a fan. The processing power to control the converter with a single chip required a higher performance than the RX62T to control three inverters (sensorless control of a compressor, a fan and a control of converters) with a single chip. In particular, Daikin’s control technique does not use a smoothing capacitor in the PFC (Power Factor Correction) control unit, hence requiring processing performance enabling a high-speed control period. (note: RX66T operates at a RXv3 core of 160MHz (5.82CoreMark/MHz)).

Sato: Although the v1 core embedded in the RX62T is fast, the speed of the v3 core is even more impressive. We also emphasize on the quick access of the flash memory. To achieve a high-speed control cycle, it is not enough to have a fast CPU clock, and if the program is read slowly from the flash, the performance will not be achieved. (note: RX66T can access the flash memory for one cycle at 120MHz) In addition, the writing speed to the flash memory is directly related to the manufacturing cost at the factory, so this is also an important point of consideration.

Taguchi: Pin compatibility is also important. We are working on a platform for developing multiple product series for multiple regions with limited resources. I think that RX microcontrollers are easy to use in platforms because they are pin compatible and upward-compatible.

Sato: Another advantage of pin compatibility is that test jigs and programs can be used with no change.

On the Left: Mr. Taguchi (left), Mr. Sato (right) and the outdoor unit equipped with RX66T (front)

On the Right: Outdoor unit control board with RX66T

Are the ventilated and humidified air conditioners (COVID-19 measures) platforms similar?

Taguchi: Of course. It is difficult to make such variations if there are no existing platforms. Ventilation is a hot topic this year, but it's something we've been working on for a long time.

Yamagata: It seems that the platform concept will have a further ripple effect.

Taguchi: For example, our heat pump water heater (EcoCute) also uses an air conditioner platform for its outdoor unit. Products other than air conditioners are standardized as much as possible, and the system is designed to provide the necessary functions to the necessary targeted products.

Yamagata: You are aiming to be environmentally friendly all the time.

Taguchi: By the way, the top series in our lineup, is also named as the RX series.

Yamagata: I am very honored! I feel the depth of the relationship between the two companies.

Sato: Either RX MCU is compatible with our circuit or Mr. Taguchi's design is really good, I have a strong impression that the RX will not spoil even after the product is sold to the market in my years of experience.

Yamagata: I’m sure it is both.

What are your expectations of RX MCUs in the future?

Taguchi: I am trying to retain the environmental data around the air conditioner, so I would like to consider a function that could utilize that data. We expect further improvements in processing performance per frequency and expansion of memory size.

Yamagata: RX72T, the high-end model of RX66T, operates at 200MHz, and of course, it is pin compatible, so you can improve performance just by replacing it. Please let us know about the next development.

Sato: Please maintain the pin compatibility. I'm saying it on behalf of Mr. Taguchi!

Yamagata: Thank you for spending time for our interview. We look forward to your continued support of Renesas and RX microcontrollers.

Visit our RX 32-Bit MCUs for Motor Control page to learn more.