Overview

Description

The heating, ventilation and air conditioning (HVAC) sector is constantly evolving and new technologies are being introduced to enhance effectiveness, decrease environmental impact, and provide superior customer service. The RealityCheck™ HVAC solution is tailored to address these requirements in response to new and more stringent environmental regulations, as well as a growing call for automation.

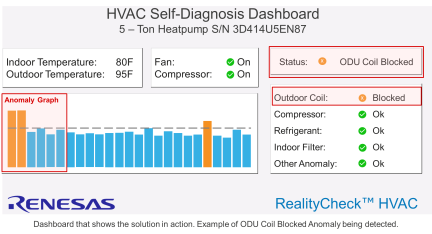

The solution is equipped with a set of AI models that can detect various conditions on your HVAC unit using vibration, temperature, and electrical signals to predict a wide range of anomalies, faults, and operating conditions. By combining machine learning and edge processing, Renesas MCUs allow your HVAC system to operate more efficiently while reducing environmental impact and improving overall user satisfaction.

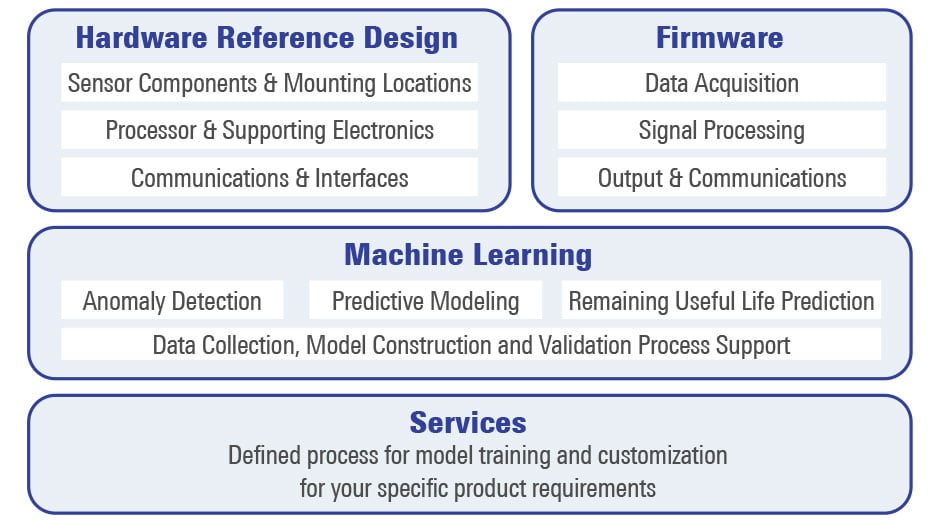

RealityCheck HVAC is a comprehensive framework that includes a hardware and firmware reference design, a set of pre-trained ML models ready to leverage for your product design, and a clearly outlined process for model training, customization, and field testing to meet your specific product requirements.

Features

RealityCheck HVAC brings machine learning algorithms tailored to detect and predict specific HVAC failure modes to small, low-power edge processors, enabling your HVAC product to monitor itself in real-time. It will enable you to:

- Integrate a cost-optimized set of sensors specifically chosen for accurate detection and prediction of specific failure modes

- Optimize sensor mounting location to minimize cost-of-manufacturing while maximizing detection/prediction accuracy

- Train and deploy a set of machine learning models specific to your requirements and equipment.

- Speed development of a deployable solution with a hardware reference design based on Renesas processors, a firmware stack for signal acquisition and processing, and edge nodes to facilitate field testing and trials

- Easily integrate into your firmware build to support your specific product-value proposition

Benefits:

- Reduced unplanned downtime

- Improve equipment performance

- Improve energy efficiency

- Reduced environmental impact

Target Devices

Documentation

|

|

|

|

|---|---|---|

| Type | Title | Date |

| Flyer | PDF 284 KB | |

1 item

|

||

Design & Development

Related Kits & Tools

Explore

Videos & Training

A look at how data-driven engineering tools can learn from examples to make a decision and ultimately be deployed automatically. Visit the Artificial Intelligence (AI) page to learn more about the Renesas approach.

News & Blog Posts

| Soaring Temperatures Demand RealityCheck™ HVAC | Blog Post | Dec 13, 2023 |

Problems We Solve

Using machine learning and edge processing, it is now possible to build HVAC units with the native ability to detect a wide range of anomalies, faults and operating conditions.

Target Conditions for Detection/Prediction:

- Blocked indoor/outdoor airflow

- Coil frosting

- Refrigerant charge issues - undercharge/overcharge

- Faulty fan

- Faulty compressor

- Failing capacitor

- Heating/cooling capacity reduction

- Filter life prediction

- Other conditions

Targeted applications include automated home and building HVAC systems for:

- Smart Home

- Smart Cities

- Smart Industry

- Building Automation

- Smart Building

Architecture