Environment

Environmental Initiatives | Response to the TCFD Proposal | Environmental Protection Goals | Climate Change Initiatives | Conserving Water | Waste Reduction Efforts | Chemical Substance Use | Eco-Product Initiatives | Eco-Communication Initiatives | Biodiversity Conservation Activities | Environmental Data and Third-Party Verification

Chemical Substance Use

The semiconductor manufacturing process uses substances and materials that pose health, safety, and environmental risks.

Renesas Group is committed to reducing environmental risks associated with semiconductor manufacturing. For this reason, we are focusing on reducing, substituting, and properly disposing of waste, while complying with laws and regulations and customer requirements.

Chemical Substance Management and System Development

We conduct various assessments through our green procurement activities and chemical substance database based on legal and regulatory information. In addition to accurately understanding the total volume of chemical substances used, we are working to reduce the use of these substances by controlling their use and emissions from the viewpoint of their hazardousness. In this way, we are conducting research and development that leads to green products and eco-factories.

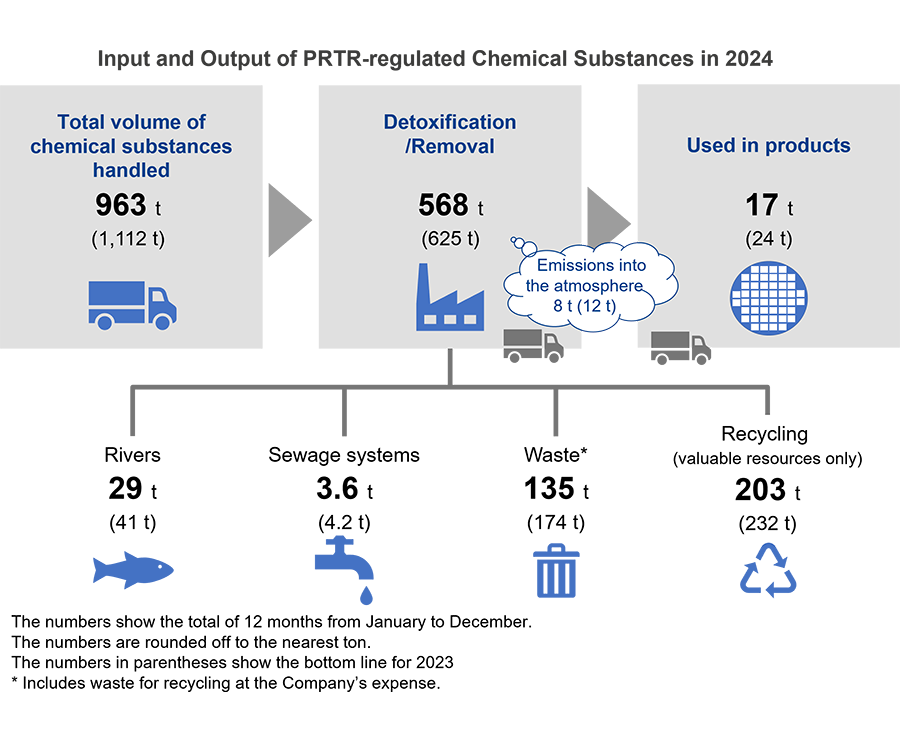

With regard to the PRTR (Note 1) Act and VOCs (Note 2), we conduct accurate balance control of the handling volume of small quantities. The balance results are not only reported to the government, but are analyzed and fed back to activities aimed at substituting chemical substance and emission reductions.

In line with the partial revision of the PRTR Law that came into effect in April 2023, Renesas has identified the substances subject to the revision, and has been working with component suppliers to prepare SDS (Note 3). At the end of March 2023, we established a management system that complies with the revised PRTR Law and started management.

Note 1: Pollutant Release and Transfer Register: a law concerning the monitoring of emissions of specified chemical substances into the environment and their management

Note 2: Volatile Organic Compounds

Note 3: Safety Data Sheet: A document that describes the properties and handling of targeted chemical substances when transferring or providing products containing chemical substances that may be dangerous or harmful to other businesses.

Income and Expenditure of Chemical Substances (Japan): PRTP Class 1 Designated Chemical Substance

Total Amount of Use (Japan) – Showing Top 6 Results

Period: January 1, 2024 to December 31, 2024

Unit: ton/year

| Decree Number | Name of Chemical Substance | CAS Number | Amount of Use | Emission Amount | Transfer Amount | Consumption Amount | Removal and Treatment Amount | Recycling (incl. Sales) | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Atmosphere | Public Bodies of Water | Soil | Sewer | Waste | |||||||

| 374 | Hydrogen fluoride and its salts | NONE | 614 | 2 | 27 | 1 | 39 | 0 | 387 | 159 | |

| 677 | Tetramethylammonium=hydroxide | NONE | 127 | 0 | 0 | 3 | 0 | 124 | 0 | ||

| 232 | N, N-Dimethylformamide | 68-12-2 | 54 | 0 | 0 | 15 | 39 | ||||

| 20 | 2-Aminoethanol | 141-43-5 | 35 | 0 | 5 | 0 | 30 | ||||

| 746 | N-Methyl-2-pyrrolidone | 872-50-4 | 27 | 1 | 14 | 0 | 1 | 11 | |||

| 80 | Xylene | NONE | 23 | 1 | 5 | 8 | 6 | 3 | |||

Understanding the Use and Emission Volume and the Introduction of Management Categories

We strive to provide products with a reduced impact to the environment as one of the most important targets in environmental protection activities. To achieve this, it is essential to reduce the environmental impact of components and materials that make up our products. For this reason, we conduct various assessments through our green procurement activities and the chemical substance database based on legal and regulatory information to determine the total amount of chemical substances used, as well as control the amount of use and emissions from the standpoint of hazardousness, in an effort to reduce them.

In addition, in consideration of the laws and regulations relating to substances of concern in global and the requirements from our customers, we classify chemical substances into four categories: "prohibited," "to be reduced," "to be managed," and "composition," and implement chemical substance control from the selection and purchase of components/material stage (including containers, packing materials, and accessories), the manufacturing process, and in products. The control categories are reviewed as appropriate.

| Definition of Chemical Substances | Management Category | |

|---|---|---|

| Renesas Management of Chemical Substances | 1. Substances that are prohibited from being contained in products or used in the manufacturing process | Prohibited Substances |

| 2. Substances promoted to be reduced by setting voluntary targets for product content and usage in the manufacturing process and emissions to the environment | Substances to be Reduced | |

| 3. Substances for which the amount of use, inventory, emissions and movements should be controlled | Substances to be Managed | |

| 4. Substances that need to be understood as constituent materials | Constituent Substances | |

For chemical substances used in components and materials, we use a "Chemical Substance Management System" in conjunction with company-wide purchasing information to accurately manage the balance of the handling volume of small quantities. It is also used to promptly respond to inquiries from customers regarding the environmental impact of products.

For chemical substance management in the manufacturing process, we established guidelines in March 2017 for the purpose of complying with environmental laws related to chemical substances, company regulations, and environmental accident prevention, and have strengthened the management of chemical substances across our sites and offices.

Efforts for Reducing VOC Emissions

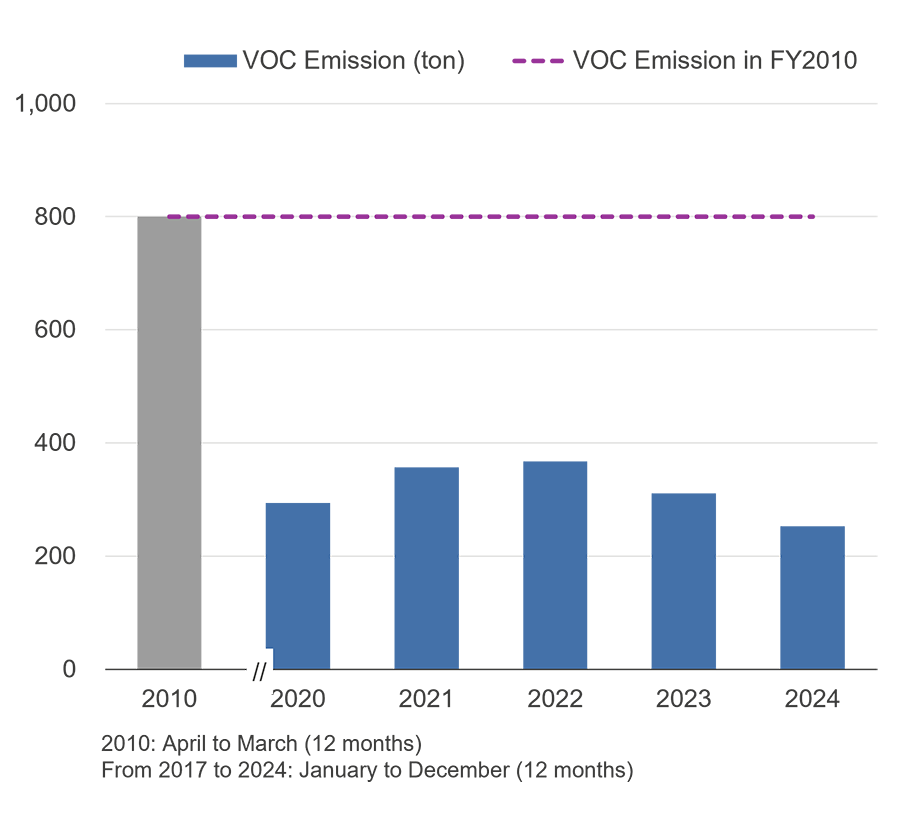

Our factories release Volatile Organic Compounds (VOCs) such as isopropylene and urethane after they have been detoxified and rendered as harmless as possible through equipment that processes organic emission gases. In addition, we are continually working to reduce VOC emissions by optimizing manufacturing processes and operating efficient production facilities.

With the target of the Air Pollution Control Law revised in 2006 (to reduce VOC emissions by 30% in March 2010 in comparison to 2000 levels), in Japan, we have gradually reduced VOC emissions, resulting in a total reduction of 36% in 2010 in comparison to 2000 levels. Since then, we have set the goal of reducing emissions to 2010 level or lower, and in 2024, we have achieved a 70% reduction in VOC emissions compared to 2010.

Protecting the Ozone Layer

We have completely eliminated the use of ozone-depleting substances (ODS) that are listed in the Montreal Protocol, such as such as chlorofluorocarbons (CFC) and hydrochlorofluorocarbons (HCFC) from our manufacturing process. In addition, we are systematically reducing the amount of CFCs used as refrigerants in freezers, refrigerators, and air conditioners in accordance with the Montreal Protocol regulations and are switching to alternative substances. At the same time, we are meticulously respecting reduction measures by collecting ODS when the equipment in question is disposed of. We are also planning to replace any equipment that uses CFCs, from large scale freezers and compact refrigerators, to equipment that systematically uses refrigerants with a low depletion potential. In 2021, no equipment will be in operation and expect all equipment to be replaced in 2024.

Compliance with Environmental Laws and Regulations

Our semiconductor products can be found in many products and are used all over the world. For this reason, we obtain information on laws and regulations of major countries in order to comply with environmental laws and regulations related to our products, reflect them in our products, and provide our customers with information regarding the content of chemical substances in a timely manner.

Substances listed in the appendix to POPs Convention (Note 4), which are required to comply internationally, are reflected in laws such as the Act on the Evaluation of Chemical Substances and Regulation of Their Manufacture (Chemical Substance Control Law) in Japan, and the POPs Convention is guaranteed. When substances designated in Annex A (Elimination) in the POPs Convention are reflected as Class 1 Specified Chemical Substances under the Chemical Substances Control Law, we classify these chemical substances in the "Prohibited Substances" category under Renesas Management of Chemical Substances. We share them globally and observe them diligently to ensure compliance.

Note 4: POPs Convention: Stockholm Convention on Persistent Organic Pollutants

Handling of Organic Fluorine Compounds

We use materials containing organic fluorochemicals as surfactants in the semiconductor manufacturing process. In recent years, there have been concerns about the environmental resilience, bioaccumulation, and long-distance mobility of organic fluorochemicals. As regulations have been tightened internationally through the Stockholm Convention on Persistent Organic Pollutants (POPs Convention), we are gradually switching to materials with lower environmental impact in collaboration with our technical divisions.

In semiconductor manufacturing, the use of organic fluorochemicals plays an important role. But due to the tightened regulations, perfluoro octane sulfonic acid (PFOS) and its salts as well as perfluorooctanesulfonyl fluoride (PFOSF) were added to Annex B (Restriction) of the POPs Convention in 2009, and it was listed as a Class I Designated Chemical Substance in the Japanese Act on the Evaluation of Chemical Substances and Regulation of Their Manufacture. In 2019, perfluorooctanoic acid (PFOA) was added to Annex A (Elimination) of the POPs Convention, and in Japan, PFOA was also listed as a Class I Designated Chemical Substance along with PFOS.

At Renesas, we have been working with our materials suppliers to proactively replace its use with alternative substances that have a lower impact on the environment. In regard to PFOS-containing materials used in the semiconductor manufacturing process, we have completed the replacement before 2010. We have also eliminated the use of PFOA-containing materials in 2020 by working together with our materials suppliers. We are continuing to actively respond to the extensive regulatory restrictions of organic fluoric compounds, as well as perfluoroalkyl compound and polyfluoroalkyl compound (PFAS).

Major Environmental Laws and Regulations Outside Japan and Our Responses

The European RoHS Directive (Note 5) and End-of-Life Vehicles (ELV) Directive (Note 6) specify threshold values for banned substances. For this reason, we receive analytical data and reports on the non-inclusion of banned substances from our suppliers for components that make up our semiconductor products. We also confirmed that they are below the thresholds by analyzing our products internally.

Note 5: An European directive limiting the content of specific hazardous substances (such as lead, mercury, cadmium, hexavalent chromium, brominated flame retardants including PBB and PBDE, and phthalates including DEHP, BBP, DBP and DIBP) in electronic and electric devices

Note 6: An European directive limiting content of lead, mercury, cadmium and hexavalent chromium in automobiles

Status of our compliance with laws and regulations

- EU RoHS

- China RoHS

- REACH(SVHC)

- Lead-free related

- Halogen-free

- RoHS compliance of tool

- Other environmental regulations and information concerning chemical substances

Initiatives in China

China’s Administrative Measures for Restrictions on the Use of Hazardous Substances in Electric and Electronic Products, also known as the Amended China RoHS II, requires labeling of designated toxic substances on final products if they contain such substances, and requires the expiration date for environmental conservation (the expiration date for safe use). Semiconductor products are not final products of electrical and electronics products, and therefore are not marked directly. However, we provide information to our customers through sales distributors on the content information and environmental protection deadlines for each type of substance.

Initiatives in Europe

Because our semiconductor products are articles that do not intentionally release chemicals (finished products), we are not required to register under the European REACH Regulation (Note 7). However, we obtain information on the content of substances of very high concern (SVHC; potentially harmful to health and safety) from our supply chain and provide it to customers.

Going forward, we will continue to work to identify information related to global laws and regulations and respond appropriately.

Note 7: REACH Rules: Regulation that requires registration, evaluation, authorization, and restriction when producing/importing chemicals in/into the EU

Contributing to SDGs

Renesas’ efforts in Chemical Substance Use contributes to these Sustainable Development Goals targets:

12.4 By 2020, achieve the environmentally sound management of chemicals and all wastes throughout their life cycle, in accordance with agreed international frameworks, and significantly reduce their release to air, water and soil in order to minimize their adverse impacts on human health and the environment

Environment

Environmental Initiatives | Response to the TCFD Proposal | Environmental Protection Goals | Climate Change Initiatives | Conserving Water | Waste Reduction Efforts | Chemical Substance Use | Eco-Product Initiatives | Eco-Communication Initiatives | Biodiversity Conservation Activities | Environmental Data and Third-Party Verification