ルネサスの耐放射線強化アナログ・スイッチは、誘電的に絶縁された耐放射線強化シリコン・ゲート(RSG)プロセス技術を用いて製造されたモノリシックデバイスで、ラッチアップ・フリー動作を保証します。

プロダクトセレクタ: 耐放射線強化スイッチ

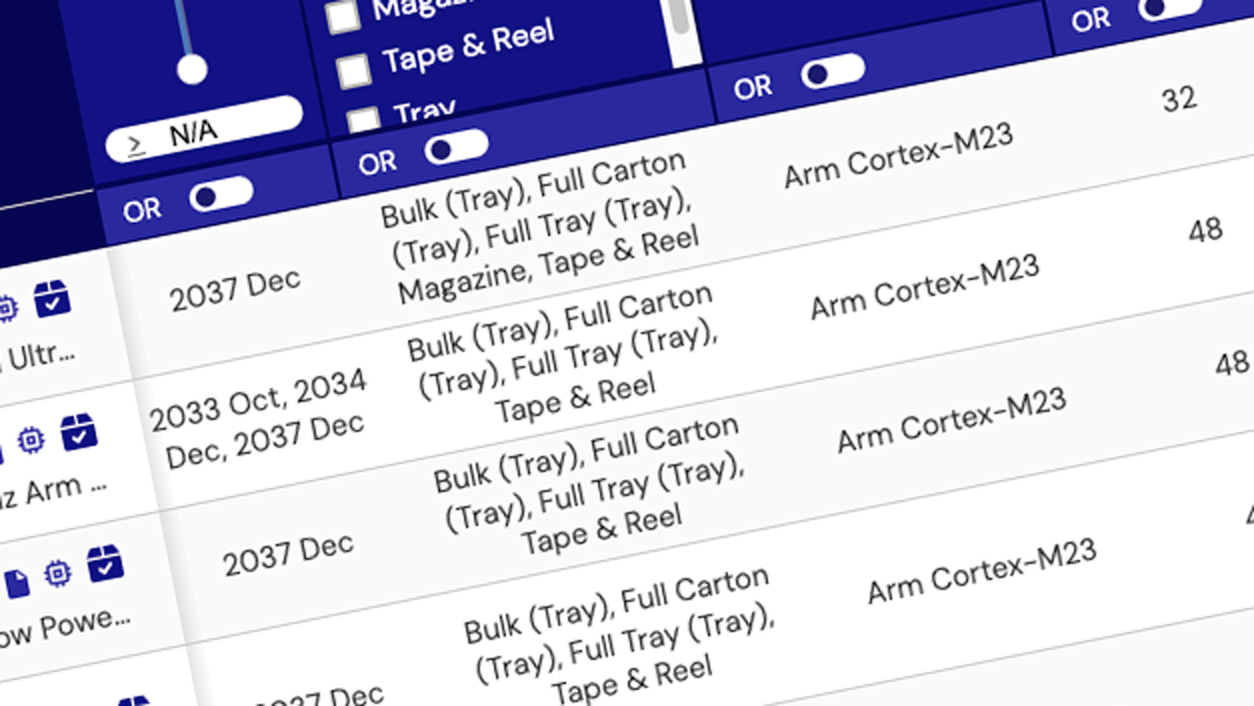

パラメトリック製品セレクタを使用してカタログ上の製品を検索してみてください。パラメータ毎に スペックを比較することでお客様の設計に適した製品が表示されます。

プロダクトセレクタドキュメント

|

|

|

|

|---|---|---|

| 分類 | タイトル | 日時 |

| カタログ | PDF 5.02 MB | |

| カタログ | PDF 467 KB | |

| 技術概要 | PDF 115 KB | |

| アプリケーションノート | PDF 338 KB | |

| アプリケーションノート | PDF 224 KB | |

5件

|

||

ビデオ&トレーニング

Over the past 19 years, the space industry has placed a higher value on understanding the effects that long-term, low dose radiation can have on ICs. Intersil's radiation testing specialist Nick van Vonno discusses why this shift has occurred and what we are doing to address this change.

Transcript

There are many different types of radiation, and indeed Intersil addresses two of these. Intersil addresses total dose testing which is basically gamma rays. Okay, and at both high and low dose rate, as we'll get into later. Intersil also addresses single event effects of a fairly broad range, and those are typically addressed by heavy ion testing.

Low dose rate testing, you have to contrast this really in order to understand this. You have to look historically at how total dose testing which is done with gamma rays, how that's been performed. Historically this has been performed at what we call high dose rate, and typically to put this in some numbers, that would run somewhere in the range of 50rad to 300rad/s.

Low dose rate, on the other hand, is a much, much slower dose rate. The generally accepted number, and the one we perform our work in, is 0.01rad/s. You see how far that's away from 300rad a second. And that can also be expressed as 10mrad/s if you'd like.

Now why are we goofing with that? And the answer is that the low dose rate is what happens in space. Dose rates in space are almost uniformly low to the order of 10mrad/s. Low dose rate radiation testing has been a, let's call it a hot topic in silicon advanced research since about 1992, okay? In 1992, some researchers out at Mich research came up with a very unusual finding which showed that certain parts that looked very good at high dose rate degrade with amazing rapidity, orders and orders of magnitude, worse at low dose rate. And so, that was not a fully intuitive result, and indeed it had to be repeated, and in the intervening 19 years there is a very large amount of work that's been done on low dose rate effects. And, as we've learned about how different parts react in low dose rate, we've, as an industry, we've swung over more towards a low dose rate testing emphasis rather than a high dose rate testing emphasis.