高度なモータ制御の必要性

最新のチェーンソーは、想像できる最も厳しい条件で動作します。 一瞬で負荷が劇的に変化する可能性があるという独自の課題があります。 広葉樹に初めて突っ込む瞬間から、結び目や異なる密度に遭遇するまで、チェーンソーのモーターは正確な制御を維持しながら即座に適応する必要があります。 従来のモータ制御システムは、これらの動的条件に苦労することが多く、性能のばらつき、効率の低下、および潜在的な安全上の懸念につながります。

プロ仕様のチェーンソーのオペレーターは、幅広い条件で信頼性の高い性能を求めています。 広葉樹に初めて突っ込む瞬間から、結び目や異なる密度に遭遇するまで、チェーンソーのモーターは正確な制御を維持しながら即座に適応する必要があります。 これに加えて、ほこり、破片、振動、天候などの過酷な環境条件が影響し、堅牢で洗練された制御ソリューションの必要性が明らかになります。

フィールド指向制御(FOC)について

フィールド指向制御は、モータ制御技術に対する変革的なアプローチを表しています。 FOCの核心は、モーターの磁場をリアルタイムで正確に制御することです。 モーターを単純な機械装置として扱う従来の制御方法とは異なり、FOCはモータ内で発生する複雑な電磁相互作用を理解し、制御します。

この高度な制御技術により、モーターの電流は、磁束を制御する要素とトルクを制御する成分と、2つの成分に分けられます。 これらのコンポーネントを独立して管理することにより、FOCはこれまでにないモーター性能の制御を実現します。 システムは、これらのパラメータを毎秒数千回連続して計算および調整し、動作条件に関係なく最適なパフォーマンスを維持します。 ルネサスは、ホールセンサに依存する従来のBLDC制御方式を置き換えるために、センサレスFOCソリューションを活用しています。 センサレスFOCアプローチは、物理センサの必要性を排除することにより、システムの複雑さを軽減し、コストを削減し、信頼性を向上させながら、正確で効率的なモータ制御を実現します。

ルネサスのチェーンソーシステムの主な機能

ルネサスのチェーンソーシステムは、チェーンソーアプリケーションの特有の課題に対処するために設計されています。

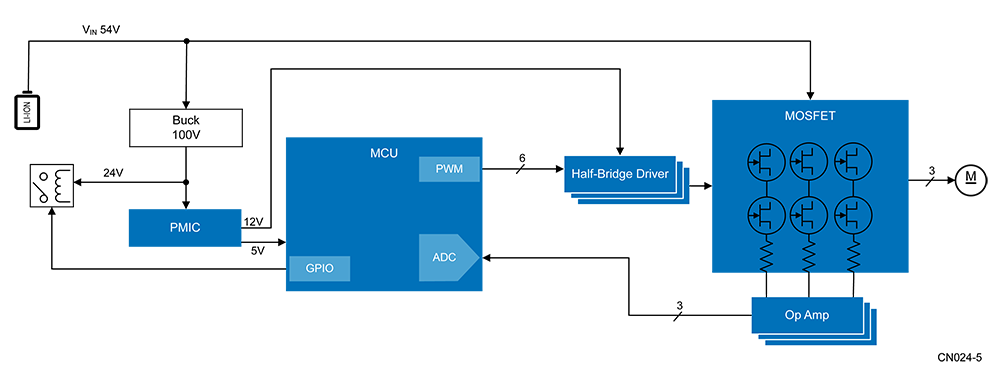

モータ制御の精度とシステム効率:RA4T1 Arm® Cortex-M33® MCUを搭載したこのシステムは、高周波インジェクション(HFI)によるフィールド指向制御などの複雑なモータ制御アルゴリズムを効率的に処理し、チェーンソーやグラインダーなどの過酷なアプリケーションでスムーズなモータ動作を実現します。 PWMタイマやADCなどの統合モータ制御ペリフェラルは、さまざまな負荷の下で正確な性能を確保し、信頼性の高い電動工具の動作を実現します。 FOCは騒音と振動を最小限に抑え、静かでスムーズな操作を提供し、より快適なユーザーエクスペリエンスを実現します。 同時に、HFIは低速またはゼロ速度でも正確なローター位置検出を可能にし、これは高トルクのスタートアップシナリオで重要です。 この高度な制御方式は、切断力と効率を向上させるだけでなく、システムの信頼性と耐久性も向上させます。

安全な操作と安全機能: このシステムは、MCUの TrustZone® テクノロジーを活用し、モーターブレーキや速度調整などの重要な安全機能を非セキュアドメインから分離し、改ざんを防止し、電動工具の安全な動作を確保します。 チェーンソーシステムは、モーターの緊急シャットダウンなどのリスクの高いタスクに対して、堅牢で改ざん防止制御を提供します。

ハイパワーハンドリングと堅牢な性能: このシステムは、単一の 汎用マイクロパワーオペアンプ と 高周波ハーフブリッジドライバーを内蔵しており、それぞれが動作効率、信頼性、および制御精度の向上に極めて重要です

。 このISL28114 は、高精度と効率性を重視して設計された低電力のレール・ツー・レール入出力オペアンプです。 チャネルあたりわずか390μAの低消費電流と広い電源電圧範囲(1.8V〜5.5V)により、ダイナミックな環境でのバッテリ寿命の延長と安定した性能を必要とするアプリケーションに最適です。 このオペアンプは、特にモータ制御およびセンサインターフェース回路において、チェーンソーでの正確な信号調整と測定を保証します。 低入力バイアス電流(最大20pA)と広い動作温度範囲(-40°C〜+125°C)により、要求の厳しい屋外条件で信頼性の高い動作が可能です。 これらの機能により、モーター制御がスムーズになり、フィードバック精度が向上し、チェーンソーの切断性能と応答性が向上します。

HIP2211高周波ハーフブリッジ・ドライバは、高電力アプリケーションでのNMOSFETの駆動に最適化されています。 強力な3Aソースと4Aシンクにより、モーターへの効率的な電力供給に必要な高速スイッチングが可能になります。 内蔵の115VDC ブートストラップ電源により、高電圧アプリケーションとの互換性が確保され、15nsの高速伝搬遅延と2nsの高精度な遅延マッチングによりスイッチング損失が最小限に抑えられ、全体的な電力効率が向上します。 チェーンソーでは、このドライバーはモーターの迅速なトルク調整をサポートし、負荷がかかる状態でも応答性と切断性能を向上させます。 低電圧ロックアウト(UVLO)保護や高いノイズ耐性などの堅牢な設計により、ヘビーデューティな切断作業でよく遭遇する電気的ノイズの多い環境での安定した動作が保証されます。

パワーマネジメント: インバータボードは、このチェーンソーターンキーソリューションの重要なコンポーネントであり、バッテリーからのDC電力をモーターのAC電力に効率的に変換できます。 最大54Vと70Aのピーク電流に対応できるため、密集した木材の切断や重工業用工具への動力供給など、要求の厳しい作業でも信頼性の高い動作が維持されます。 その設計は、ポータブルツール用の小型軽量モーターから、プロ仕様の機器用の高トルクモーターまで、幅広いモーターサイズをサポートし、メーカーに優れた汎用性を提供します。 DC-AC変換プロセスを最適化することで、インバーターボードはバッテリー効率を最大化し、エネルギー損失と発熱を減らし、ランタイムとバッテリー寿命の両方を延長します。 この効率性は、コードレスツールで特に価値があり、ユーザーは頻繁に充電することなく、より長く作業することができます。

高効率なパワーマネジメントソリューションであるRAA212831の統合により、このターンキーソリューションの全体的なパフォーマンスがさらに向上します。 FETを内蔵したこの72V、0.5A降圧レギュレータは、優れた電力変換効率を提供するとともに、5Vと3.3Vのデュアル低ドロップアウト(LDO)出力により、システム全体の電源設計を簡素化します。 電力損失を最小限に抑え、安定した電圧レギュレーションを提供することにより、このRAA212831は、動的負荷下でもインバータボードと関連コンポーネントの信頼性の高い動作を維持します。 また、そのコンパクトな統合設計は、PCBサイズの縮小と製造の合理化にも役立ち、スペースに制約のある高性能アプリケーションに最適です。

さらに、インバータボードの堅牢な構造と高品質のコンポーネントにより、負荷の変動や温度の変化などの過酷な条件でも一貫した性能が確保され、プロフェッショナル用途に高い信頼性を発揮します。 高負荷下でも安定した電力供給を維持する能力は、モーターの性能を向上させ、精密切断や困難なアプリケーションに必要なトルクと速度を提供します。 電力効率、耐久性、適応性に重点を置いたインバーターボードは、チェーンソーターンキーソリューションを向上させ、専門家やDIY愛好家のニーズを満たすように調整された強力で効率的なツールを提供します。

製品開発の加速: 設計ファイルを備えたターンキーソリューションであり、チェーンソーや電動工具などの最終製品にシームレスに統合するために必要なすべてのハードウェア、ソフトウェア、およびドキュメントを含む、すぐに使用できるシステムです。 PCB、ファームウェア、リファレンスデザイン用の事前テスト済みデザインファイルを提供することで、メーカーは市場投入までの時間を短縮し、広範な研究開発の必要性を最小限に抑えて開発コストを削減し、製品の差別化に集中することができます。 また、付属の設計ファイルによりカスタマイズ性が確保されるため、メーカーはさまざまなモーターサイズや高度な安全機能など、特定の製品要件に合わせてソリューションを調整できます。

チェーンソーを超えて

このソリューションは、ドリルやグラインダーから丸鋸やヘビーデューティ産業機器まで、さまざまな電動工具にシームレスに拡張できます。 このシステムは、フィールド指向の制御と高周波注入を利用して、さまざまなアプリケーションにわたって正確な動作とスムーズなパフォーマンスを実現します。 アングルグラインダーのような工具は、さまざまな負荷下でのFOCのトルク制御の恩恵を受け、HFIはドリルの低速始動に不可欠な正確なローター位置決めを提供します。 インバータボードの汎用性の高い設計は、さまざまな電圧および電流要件に対応し、コンパクトなバッテリー駆動ツールや大規模な産業用システムのエネルギー効率を最適化します。 ターンキー設計により、メーカーは製品開発を簡素化し、大規模な研究開発を行わずにさまざまな工具仕様に迅速に適応できます。この柔軟性により、このソリューションは複数の製品ラインへの拡張に最適で、プロフェッショナルユーザーやDIYユーザー固有の要求に対応しながら、イノベーションを促進します。

まとめ

このソリューションは、最新のモータ制御技術の革新的な進展であり、電動工具メーカーに高度な機能を提供します。 高精度のアルゴリズム、セキュアな動作、効率的な電力処理により、要求の厳しいアプリケーションの性能ニーズを満たしながら、事前にテスト済みの設計ファイルとカスタマイズ可能なオプションで開発を簡素化します。 さまざまなツールにスケーラブルに対応しているため、メーカーはエネルギー効率を最適化し、コンパクトなコードレスデバイスからヘビーデューティ産業機械まで、あらゆるものに最先端の機能を提供できます。 市場投入までの時間を短縮することで、メーカーは顧客の期待に応える差別化された製品を生み出すことができます。

ルネサスのパワーモータ制御ソリューションの詳細については、高度なモータ制御技術ソリューションをご覧いただき、このソリューションおよびルネサスの他のウィニングコンビネーションについては、 www.renesas.com/win をご覧ください。