Evaluation Kit for ZSSC415x

The ZSSC415xKIT Evaluation Kit provides the hardware needed for configuration, calibration and evaluation of the ZSSC4151 Sensor Signal Conditioner (SSC) IC. The user's...

The ZSSC4151 is a CMOS integrated circuit for highly accurate amplification and sensor-specific correction of resistive bridge sensor signals. Digital compensation of sensor offset, sensitivity, temperature drift, and non-linearity is accomplished via an internal 16-bit RISC microcontroller running a correction algorithm, with calibration coefficients stored in an integrated EEPROM. The ZSSC4151 is adjustable to nearly all resistive bridge sensor types. Measured values are provided at the analog voltage output and at the optional digital I2C or the ZACwire™ interface, also referred to as the one-wire interface (OWI). The digital interfaces can be used for a simple PC-controlled calibration procedure to program a set of calibration coefficients into an on-chip EEPROM. The ZSSC4151 and the calibration equipment communicate digitally, so the noise sensitivity is greatly reduced. Digital calibration helps keep assembly cost low as no trimming by external devices or lasers is needed.

The ZSSC415xKIT Evaluation Kit provides the hardware needed for configuration, calibration and evaluation of the ZSSC4151 Sensor Signal Conditioner (SSC) IC. The user's...

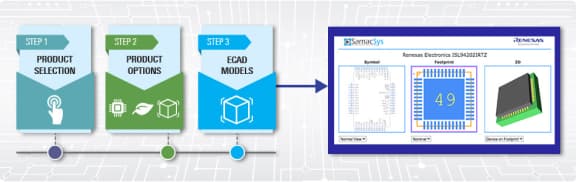

[製品選択]テーブル内の製品名をクリックするとSamacSysが提供する回路図シンボル、PCBフットプリント、3D CADモデルがご確認いただけます。 お探しのシンボルやモデルが見つからない場合、Webサイトから直接リクエストできます。

適用されたフィルター

The ZSSC4151 is a CMOS integrated circuit for highly accurate amplification and sensor-specific correction of resistive bridge sensor signals. Digital compensation of sensor offset, sensitivity, temperature drift, and non-linearity is accomplished via an internal 16‑bit RISC microcontroller running a correction algorithm, with calibration coefficients stored in an integrated EEPROM.

For more information about the ZSSC4151 visit www.IDT.com/ZSSC4151.

TRANSCRIPT

Hi, I'm Chris Anderson at the E.U Web tech lab and today we'll discuss IDT's ZSSC415X family of parts which are automotive sensor signal conditioners that provide an analog output with the benefits of a digital core. The ZSSC4151 is the first product in the family and features a 16 bit risk MCU, interfaced to an analog front end with 12 to 18 bits of resolution and which can be used within any type of bridge sensor.

The digital core enables a correction algorithm to internally handle compensation for factors such as thermal drift, non-linearity and sensor offset. These factors are stored in the on chip EPROM. Calibration is also controlled digitally, which reduces noise sensitivity and eliminates the need for trimming.

Once the measured value's digitally corrected, it is then output as an analog signal through a 12 bit deck or over the serial interface. The ZSSE4151 is AEC-Q100 qualified and targeted at automotive applications, including pressure sensors and temperature sensors. The evaluation kit consists of a communication board, the sensor signal conditioner board and a board with a potentiometer for simulating sensor input.

So once you've connected the board for the evaluation kit and then connected via USB to your computer, open the ZSSC415X application. On the far right side you should see an entry here that indicates your device is connected properly to the computer and recognized by the software. The first thing you need to do is load the GUI configuration file and accept all the prompts as you go and then load the NVM dump file and then 'write all to NVM'. Once that's complete you'll see the green checked mark down here with NVM next to it indicating that data was successfully written.

Now we can start collecting data and using this simulated pressure sensor which is just a potentiometer, you can see that as I adjust it, the data being reported in the program adjusts as well. And you can also go look at temperature data which right now it says it's about 19 degrees in the room which...well that is cold, I do believe that's correct because it is quite chilly in the room. And you can also look at the raw pressure data.

Now this hasn't been calibrated so if we click on the calibration tab, verify that all your settings are as you see them here and then what we'll do is go down to P1 and we'll spin the potentiometer fully counterclockwise, click 'Acquire data' and we'll go to P2 and then turn that fully clockwise so that it's at its maximum value and acquire data again and then you can click 'Calculate' and in this window down here you can see the calculations that are being done.

If you scroll all the way to the bottom, there's an output and if you hover over that, you can see the full output of the calibration. If we write coefficients to NVM, that will write all the data to the non-volatile memory and then if we come back here to 'main' and start collecting data again, you'll now see that since I left it at its maximum and back here our target min and our target max were 90% and 10%, that data will show up as the 90% value.

And as we adjust down, this should put me in about half way, so I should be setting it about 50% and as I rotate counterclockwise, if I pass the mid-point, that will put me at about 50% and then as I continue counterclockwise, that should bring me down to 10%. One of the things that I really like about ZMDI's boards is you can see on the sensor conditioner board. You have full access to all the pins so you can hook up your own external sensors, you can hook up your own instrumentation so that you can really truly evaluate the board.

And on the software side and this is very much in ZMDI's nature, they give you access to more settings than you can possibly imagine and so there's really no limit in this evaluation kit for evaluating the ZMDI ZSSC415X family of products.

IDT ZSSC4151 provides users needing an analog signal with the benefits of digital calibration and compensation. For more information, visit idt.com.